What is Global Manufacturing Maintenance Software Market?

The Global Manufacturing Maintenance Software Market is a rapidly evolving sector that plays a crucial role in ensuring the smooth operation of manufacturing processes worldwide. This market encompasses a range of software solutions designed to optimize the maintenance of manufacturing equipment and facilities. These software solutions help manufacturers reduce downtime, improve efficiency, and extend the lifespan of their machinery. By utilizing advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning, these software systems can predict equipment failures before they occur, schedule maintenance activities, and manage spare parts inventory effectively. The market is driven by the increasing demand for automation and the need to enhance productivity in manufacturing operations. As industries continue to embrace digital transformation, the adoption of manufacturing maintenance software is expected to grow, providing manufacturers with the tools they need to maintain a competitive edge in the global market. This software not only helps in reducing operational costs but also ensures compliance with safety and regulatory standards, making it an indispensable asset for modern manufacturing enterprises.

Equipment Monitoring and Diagnostics Software, Preventive Maintenance Planning Software, Work Order Management and Execution Software, Spare Parts Management Software, Others in the Global Manufacturing Maintenance Software Market:

Equipment Monitoring and Diagnostics Software is a critical component of the Global Manufacturing Maintenance Software Market. This software provides real-time data on the performance and condition of manufacturing equipment. By continuously monitoring parameters such as temperature, vibration, and pressure, it can detect anomalies that may indicate potential equipment failures. This early detection allows maintenance teams to address issues before they lead to costly downtime. The software often incorporates advanced analytics and machine learning algorithms to predict failures and recommend corrective actions. Preventive Maintenance Planning Software is another essential tool in this market. It helps manufacturers schedule regular maintenance activities based on equipment usage and historical performance data. By planning maintenance activities in advance, manufacturers can minimize unexpected breakdowns and extend the lifespan of their equipment. This software also helps in optimizing maintenance resources, ensuring that technicians are available when needed and that spare parts are in stock. Work Order Management and Execution Software streamlines the process of creating, assigning, and tracking maintenance work orders. It ensures that maintenance tasks are completed efficiently and on time. This software provides a centralized platform for managing all maintenance activities, allowing teams to prioritize tasks, allocate resources, and track progress. It also facilitates communication between maintenance teams and other departments, ensuring that everyone is informed about the status of maintenance activities. Spare Parts Management Software is crucial for maintaining an optimal inventory of spare parts. It helps manufacturers track the usage of spare parts, manage inventory levels, and reorder parts when necessary. By ensuring that the right parts are available when needed, this software reduces downtime and improves the efficiency of maintenance operations. Other software solutions in the Global Manufacturing Maintenance Software Market include tools for asset management, compliance tracking, and reporting. These solutions help manufacturers manage their assets more effectively, ensure compliance with industry regulations, and generate reports on maintenance activities and performance metrics. Together, these software solutions provide a comprehensive approach to managing maintenance activities in manufacturing environments, helping manufacturers improve efficiency, reduce costs, and enhance the reliability of their operations.

Electronics Manufacturing, Aerospace Manufacturing, Automobile Manufacturing, Machinery Manufacturing, Others in the Global Manufacturing Maintenance Software Market:

The Global Manufacturing Maintenance Software Market finds extensive usage across various industries, including electronics, aerospace, automobile, and machinery manufacturing. In the electronics manufacturing sector, this software is used to ensure the smooth operation of complex production lines. Electronics manufacturing involves intricate processes that require precise control and monitoring. Maintenance software helps in tracking the performance of equipment, predicting failures, and scheduling maintenance activities to prevent disruptions in production. In the aerospace manufacturing industry, where safety and reliability are paramount, maintenance software plays a critical role in ensuring that equipment and facilities are in optimal condition. The software helps in tracking the maintenance history of equipment, ensuring compliance with safety regulations, and managing spare parts inventory. This is crucial in an industry where even minor equipment failures can have significant consequences. In the automobile manufacturing sector, maintenance software is used to optimize the performance of production lines and ensure the timely delivery of vehicles. The software helps in monitoring the condition of equipment, scheduling preventive maintenance activities, and managing spare parts inventory. This ensures that production lines operate smoothly and efficiently, reducing downtime and improving productivity. In machinery manufacturing, maintenance software is used to manage the maintenance of heavy machinery and equipment. The software helps in tracking the performance of machinery, predicting failures, and scheduling maintenance activities. This is essential in an industry where equipment downtime can result in significant financial losses. Other industries that benefit from the Global Manufacturing Maintenance Software Market include food and beverage, pharmaceuticals, and chemicals. In these industries, maintenance software helps in ensuring the smooth operation of production lines, maintaining product quality, and complying with industry regulations. Overall, the Global Manufacturing Maintenance Software Market provides manufacturers with the tools they need to optimize their maintenance activities, improve efficiency, and maintain a competitive edge in their respective industries.

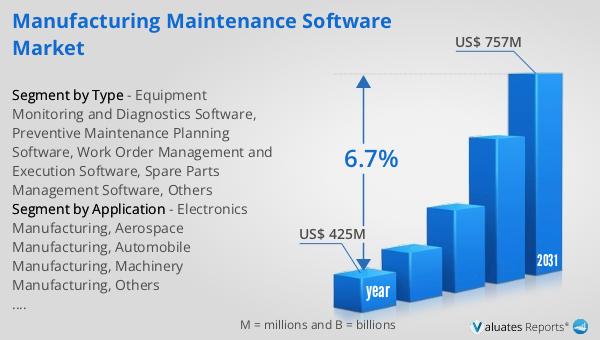

Global Manufacturing Maintenance Software Market Outlook:

The global market for Manufacturing Maintenance Software was valued at $425 million in 2024 and is anticipated to expand to a revised size of $757 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.7% over the forecast period. This growth trajectory underscores the increasing importance of maintenance software in the manufacturing sector. As industries continue to embrace digital transformation, the demand for advanced maintenance solutions is expected to rise. Manufacturers are increasingly recognizing the benefits of using software to optimize their maintenance activities, reduce downtime, and improve efficiency. The adoption of technologies such as IoT, AI, and machine learning is driving the development of more sophisticated maintenance software solutions that can predict equipment failures, schedule maintenance activities, and manage spare parts inventory effectively. This is particularly important in industries where equipment downtime can result in significant financial losses. The growth of the Global Manufacturing Maintenance Software Market is also being driven by the increasing focus on safety and regulatory compliance. Manufacturers are using maintenance software to ensure that their equipment and facilities meet industry standards and regulations. This is essential in industries such as aerospace and pharmaceuticals, where safety and compliance are critical. Overall, the Global Manufacturing Maintenance Software Market is poised for significant growth in the coming years, providing manufacturers with the tools they need to maintain a competitive edge in the global market.

| Report Metric | Details |

| Report Name | Manufacturing Maintenance Software Market |

| Accounted market size in year | US$ 425 million |

| Forecasted market size in 2031 | US$ 757 million |

| CAGR | 6.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | WONDER, ALICE Technologies, Chetu, DNV, Fluix, GreenGate AG, Inetum, Offshare, ONYX Insight, Openwind, Power Factors, QBI Solutions, SeaPlanner, Siemens, SkySpecs, WindDeep |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |