What is Global High-Speed Precision Online Dispensing Machine Market?

The Global High-Speed Precision Online Dispensing Machine Market is a specialized segment within the broader manufacturing and automation industry. These machines are designed to dispense precise amounts of materials at high speeds, which is crucial for industries that require exact measurements and rapid production processes. The market for these machines is driven by the increasing demand for automation and precision in manufacturing processes across various sectors. These machines are used in applications where accuracy and speed are paramount, such as in the electronics, medical, and automotive industries. The technology behind these machines allows for the efficient and accurate dispensing of adhesives, sealants, lubricants, and other materials, which is essential for maintaining product quality and consistency. As industries continue to evolve and demand more sophisticated manufacturing solutions, the market for high-speed precision online dispensing machines is expected to grow, driven by advancements in technology and the need for more efficient production methods.

Contact Dispensing, Non-contact Jet Dispensing in the Global High-Speed Precision Online Dispensing Machine Market:

Contact dispensing and non-contact jet dispensing are two primary methods used in the Global High-Speed Precision Online Dispensing Machine Market. Contact dispensing involves the direct application of materials onto a substrate, where the dispensing nozzle physically touches the surface. This method is often used for applications requiring high precision and control, such as in the electronics industry for applying solder paste or adhesives. The advantage of contact dispensing is its ability to deliver materials with high accuracy and repeatability, making it ideal for tasks that require meticulous attention to detail. However, it may not be suitable for all applications, especially those involving delicate or uneven surfaces, as the physical contact can potentially damage the substrate or lead to inconsistent results. On the other hand, non-contact jet dispensing offers a different approach by allowing materials to be dispensed without the nozzle touching the substrate. This method uses a jetting mechanism to propel droplets of material onto the target surface, which is particularly useful for applications where contact with the substrate is undesirable or impractical. Non-contact jet dispensing is highly versatile and can be used for a wide range of materials, including adhesives, coatings, and inks. It is especially beneficial for applications involving complex geometries or hard-to-reach areas, as the lack of physical contact allows for greater flexibility in dispensing. Additionally, non-contact jet dispensing can achieve high speeds and throughput, making it suitable for high-volume production environments. Both contact and non-contact dispensing methods have their unique advantages and limitations, and the choice between them often depends on the specific requirements of the application. Factors such as the type of material being dispensed, the substrate characteristics, and the desired level of precision and speed all play a role in determining the most appropriate dispensing method. In some cases, a combination of both methods may be used to achieve optimal results, leveraging the strengths of each approach to meet the demands of complex manufacturing processes. The Global High-Speed Precision Online Dispensing Machine Market continues to evolve as new technologies and innovations emerge, offering improved performance and capabilities. Manufacturers are constantly seeking ways to enhance the precision, speed, and versatility of dispensing machines to meet the growing demands of various industries. As a result, advancements in areas such as robotics, machine vision, and software integration are driving the development of more sophisticated dispensing solutions. These advancements not only improve the efficiency and accuracy of dispensing processes but also enable greater customization and adaptability to meet the specific needs of different applications. In conclusion, contact dispensing and non-contact jet dispensing are two fundamental methods within the Global High-Speed Precision Online Dispensing Machine Market, each offering distinct advantages for different applications. As industries continue to demand higher levels of precision and efficiency, the market for these machines is expected to grow, driven by ongoing technological advancements and the need for more sophisticated manufacturing solutions.

Electronics and Semiconductor Industry, Medical Industry, New Energy Industry, Communications Industry, Optical Industry, Aerospace Industry, Others in the Global High-Speed Precision Online Dispensing Machine Market:

The Global High-Speed Precision Online Dispensing Machine Market finds extensive usage across various industries, each benefiting from the precision and efficiency these machines offer. In the electronics and semiconductor industry, these machines are crucial for applying solder paste, adhesives, and other materials with high accuracy, ensuring the reliability and performance of electronic components. The ability to dispense materials precisely is essential for maintaining the integrity of delicate circuits and components, which are becoming increasingly complex and miniaturized. As the demand for smaller and more powerful electronic devices continues to rise, the need for high-speed precision dispensing machines in this industry is expected to grow. In the medical industry, these machines play a vital role in the production of medical devices and equipment, where precision and consistency are paramount. They are used for dispensing adhesives, coatings, and other materials in the assembly of medical devices, ensuring that each component meets stringent quality standards. The ability to dispense materials with high precision is critical for maintaining the safety and efficacy of medical devices, which are subject to rigorous regulatory requirements. As the medical industry continues to innovate and develop new technologies, the demand for high-speed precision dispensing machines is likely to increase. The new energy industry also benefits from the capabilities of high-speed precision dispensing machines, particularly in the production of batteries and other energy storage devices. These machines are used to apply materials such as electrolytes and sealants with high accuracy, ensuring the performance and longevity of energy storage systems. As the demand for renewable energy solutions and electric vehicles continues to grow, the need for efficient and precise dispensing machines in this industry is expected to rise. In the communications industry, high-speed precision dispensing machines are used for the assembly of communication devices and infrastructure, where precision and reliability are critical. These machines are used to apply adhesives, coatings, and other materials in the production of components such as antennas, connectors, and circuit boards. The ability to dispense materials with high precision is essential for maintaining the performance and reliability of communication systems, which are becoming increasingly complex and interconnected. The optical industry also relies on high-speed precision dispensing machines for the production of optical components and devices. These machines are used to apply coatings, adhesives, and other materials with high accuracy, ensuring the quality and performance of optical products. The ability to dispense materials precisely is critical for maintaining the optical properties of lenses, mirrors, and other components, which are essential for a wide range of applications, from consumer electronics to scientific instruments. In the aerospace industry, high-speed precision dispensing machines are used for the assembly of aircraft components and systems, where precision and reliability are paramount. These machines are used to apply adhesives, sealants, and other materials with high accuracy, ensuring the structural integrity and performance of aerospace systems. The ability to dispense materials precisely is critical for maintaining the safety and reliability of aircraft, which are subject to stringent regulatory requirements. In addition to these industries, high-speed precision dispensing machines are also used in various other sectors, including automotive, packaging, and consumer goods. The versatility and precision of these machines make them suitable for a wide range of applications, from applying adhesives and sealants to dispensing coatings and lubricants. As industries continue to demand higher levels of precision and efficiency, the market for high-speed precision dispensing machines is expected to grow, driven by ongoing technological advancements and the need for more sophisticated manufacturing solutions.

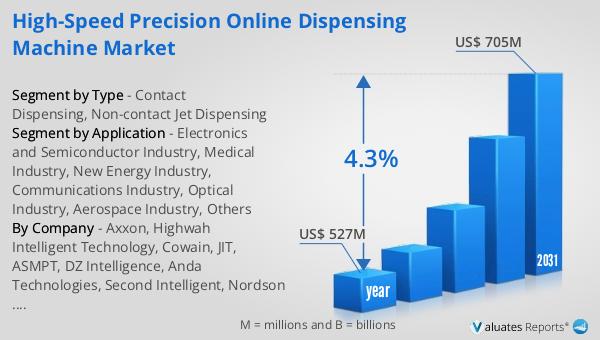

Global High-Speed Precision Online Dispensing Machine Market Outlook:

The global market for High-Speed Precision Online Dispensing Machines was valued at approximately 527 million USD in 2024. This market is anticipated to expand significantly, reaching an estimated size of 705 million USD by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.3% over the forecast period. The steady increase in market size reflects the rising demand for precision and efficiency in manufacturing processes across various industries. As industries continue to evolve and require more sophisticated manufacturing solutions, the need for high-speed precision dispensing machines is expected to grow. These machines offer the ability to dispense materials with high accuracy and speed, which is essential for maintaining product quality and consistency. The market's growth is driven by advancements in technology and the increasing demand for automation in manufacturing processes. As a result, manufacturers are investing in high-speed precision dispensing machines to enhance their production capabilities and meet the growing demands of their customers. The market outlook for high-speed precision dispensing machines is positive, with continued growth expected as industries seek more efficient and precise manufacturing solutions.

| Report Metric | Details |

| Report Name | High-Speed Precision Online Dispensing Machine Market |

| Accounted market size in year | US$ 527 million |

| Forecasted market size in 2031 | US$ 705 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Axxon, Highwah Intelligent Technology, Cowain, JIT, ASMPT, DZ Intelligence, Anda Technologies, Second Intelligent, Nordson Adhesive Dispensing, GKG Precision Machine, Enjess smart system, Musashi Engineering, Eagle Technologies, Shenzhen Surpass Industrial Equipment, HAN'S LASER, Mingseal, HONG ZHAN, PIE, Taiwan Leh-Yeh Technology, Desen Precision, MEST, UICK, SHENZHEN PEACH AUTOMATION TECHNOLOGY, SAMON, GK-PRETECH, DONGGUAN NASHENG ELECTRONIC EQUIPMENT TECHNOLOGY, BOJAY, SHENZHEN XINNUO PRECISION MACHINE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |