What is Global Dry Particle Ore Separator Market?

The Global Dry Particle Ore Separator Market is a specialized segment within the mining industry that focuses on the separation of ore particles without the use of water. This market is crucial for regions where water scarcity is a significant concern, as it provides an efficient and environmentally friendly alternative to traditional wet separation methods. Dry particle ore separators are used to sort and separate valuable minerals from waste material, enhancing the efficiency of mining operations. These separators utilize various technologies to achieve precise separation, ensuring that the extracted ore is of high quality and purity. The market is driven by the increasing demand for minerals and metals, coupled with the need for sustainable mining practices. As industries continue to seek ways to reduce their environmental footprint, the adoption of dry particle ore separators is expected to grow. This market encompasses a range of technologies and equipment designed to meet the diverse needs of the mining sector, offering solutions that are both cost-effective and environmentally responsible. The global dry particle ore separator market is poised for growth as it aligns with the broader trends of sustainability and resource efficiency in the mining industry.

XRT Separator, LIBS Separator, Others in the Global Dry Particle Ore Separator Market:

In the realm of the Global Dry Particle Ore Separator Market, several technologies stand out, including XRT (X-ray Transmission) Separator, LIBS (Laser-Induced Breakdown Spectroscopy) Separator, and other innovative solutions. The XRT Separator is a cutting-edge technology that uses X-ray transmission to distinguish between different types of ore based on their density and atomic composition. This method is highly effective for sorting ores with varying densities, such as those found in metal mining. By analyzing the X-ray images, the separator can accurately identify and separate valuable minerals from waste material, enhancing the efficiency and precision of the mining process. The XRT Separator is particularly beneficial for operations where water usage is restricted, as it operates without the need for water, making it an environmentally friendly option. On the other hand, the LIBS Separator employs laser-induced breakdown spectroscopy to analyze the elemental composition of ore particles. This technology involves directing a high-energy laser pulse at the ore, creating a plasma that emits light. By analyzing the emitted light, the LIBS Separator can determine the elemental makeup of the ore, allowing for precise sorting and separation. This method is advantageous for its ability to provide real-time analysis and sorting, making it a valuable tool for mining operations that require rapid and accurate ore classification. The LIBS Separator is versatile and can be used for a wide range of ores, including both metallic and non-metallic minerals. In addition to XRT and LIBS Separators, the market also includes other innovative technologies designed to meet the diverse needs of the mining industry. These may include magnetic separators, electrostatic separators, and optical sorters, each offering unique advantages depending on the specific requirements of the mining operation. Magnetic separators, for instance, are ideal for separating magnetic minerals from non-magnetic ones, while electrostatic separators use electrical charges to differentiate between particles. Optical sorters, on the other hand, utilize cameras and sensors to identify and sort particles based on color and shape. The choice of separator technology depends on various factors, including the type of ore being processed, the desired purity level, and the environmental considerations of the mining operation. As the demand for minerals and metals continues to rise, the Global Dry Particle Ore Separator Market is expected to see increased adoption of these advanced technologies. Mining companies are increasingly looking for solutions that not only enhance operational efficiency but also align with sustainability goals. By investing in dry particle ore separators, these companies can reduce their environmental impact while maximizing the yield and quality of their extracted minerals. Overall, the market for dry particle ore separators is characterized by innovation and a commitment to sustainable mining practices, making it a vital component of the modern mining industry.

Metal Mining Industry, Non-Metallic Mining Industry in the Global Dry Particle Ore Separator Market:

The Global Dry Particle Ore Separator Market plays a significant role in both the metal mining industry and the non-metallic mining industry, offering solutions that enhance efficiency and sustainability. In the metal mining industry, dry particle ore separators are used to extract valuable metals such as gold, silver, copper, and iron from ore deposits. These separators are particularly beneficial in regions where water resources are limited, as they eliminate the need for water in the separation process. By using technologies such as XRT and LIBS, mining companies can achieve precise separation of metal ores, ensuring that the extracted metals are of high quality and purity. This not only improves the efficiency of mining operations but also reduces the environmental impact by minimizing water usage and waste generation. In the non-metallic mining industry, dry particle ore separators are used to process minerals such as limestone, gypsum, and phosphate. These minerals are essential for various industrial applications, including construction, agriculture, and manufacturing. The use of dry particle ore separators in non-metallic mining allows for the efficient extraction of these minerals without the need for water, making it an ideal solution for arid regions. By employing advanced technologies, mining companies can achieve high levels of precision in separating valuable minerals from waste material, ensuring that the extracted products meet industry standards and customer requirements. The adoption of dry particle ore separators in both the metal and non-metallic mining industries is driven by the need for sustainable and efficient mining practices. As environmental regulations become more stringent and the demand for minerals continues to grow, mining companies are increasingly turning to dry separation technologies to meet these challenges. By reducing water usage and minimizing waste, dry particle ore separators contribute to the overall sustainability of mining operations, helping companies to achieve their environmental and social responsibility goals. Furthermore, the use of dry particle ore separators can lead to significant cost savings for mining companies. By eliminating the need for water in the separation process, companies can reduce their operational costs and improve their bottom line. Additionally, the precision and efficiency of these separators can lead to higher yields and better quality products, further enhancing the profitability of mining operations. Overall, the Global Dry Particle Ore Separator Market offers valuable solutions for both the metal and non-metallic mining industries, providing technologies that enhance efficiency, sustainability, and profitability.

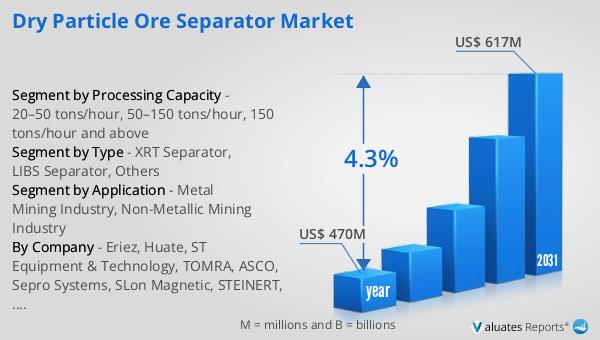

Global Dry Particle Ore Separator Market Outlook:

The global market for Dry Particle Ore Separator was valued at $470 million in 2024 and is anticipated to grow to a revised size of $617 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.3% during the forecast period. This growth trajectory underscores the increasing demand for efficient and sustainable mining solutions across the globe. As industries continue to prioritize environmental sustainability and resource efficiency, the adoption of dry particle ore separators is expected to rise. These separators offer a viable alternative to traditional wet separation methods, particularly in regions where water scarcity is a pressing concern. By eliminating the need for water in the separation process, dry particle ore separators not only reduce environmental impact but also offer cost savings for mining companies. The projected growth of the market is indicative of the broader trends in the mining industry, where there is a growing emphasis on sustainable practices and technologies that enhance operational efficiency. As the market continues to evolve, it is likely to see further innovation and development, with new technologies and solutions emerging to meet the diverse needs of the mining sector. Overall, the Global Dry Particle Ore Separator Market is poised for significant growth, driven by the increasing demand for sustainable mining solutions and the need for efficient resource management.

| Report Metric | Details |

| Report Name | Dry Particle Ore Separator Market |

| Accounted market size in year | US$ 470 million |

| Forecasted market size in 2031 | US$ 617 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Processing Capacity |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Eriez, Huate, ST Equipment & Technology, TOMRA, ASCO, Sepro Systems, SLon Magnetic, STEINERT, Metso, Binder+Co, Redwave, Comex Group, Mogensen, Anhui Zhongke Optic-electronic Color Sorter Machinery, Shandong Huate Magnet Technology, Nanchang Mineral Systems, Hefei Angelon Electronics, Hefei Taihe Intelligent Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |