What is Global Acid Zinc Plating Intermediate Market?

The Global Acid Zinc Plating Intermediate Market is a specialized segment within the broader chemical and materials industry, focusing on the production and distribution of intermediates used in acid zinc plating processes. Acid zinc plating is a method used to apply a protective zinc coating to metal surfaces, enhancing their corrosion resistance and aesthetic appeal. This market is driven by the demand for durable and corrosion-resistant metal products across various industries, including automotive, electronics, and industrial machinery. The intermediates used in this process are crucial as they facilitate the deposition of zinc onto metal substrates, ensuring uniform coverage and optimal performance. The market is characterized by a diverse range of products, each tailored to specific applications and performance requirements. As industries continue to prioritize sustainability and efficiency, the demand for advanced plating intermediates that offer improved environmental profiles and cost-effectiveness is expected to grow. This market is also influenced by technological advancements and regulatory changes, which can impact the development and adoption of new plating solutions. Overall, the Global Acid Zinc Plating Intermediate Market plays a vital role in supporting the manufacturing and maintenance of high-quality metal products across various sectors.

Solid, Liquid in the Global Acid Zinc Plating Intermediate Market:

In the Global Acid Zinc Plating Intermediate Market, the products are generally categorized into two main types: solid and liquid intermediates. Solid intermediates are typically in the form of powders or granules, which are dissolved in a solution to create the plating bath. These solid forms are often preferred for their ease of storage and handling, as they are less prone to spillage and contamination compared to their liquid counterparts. Solid intermediates are also known for their stability and long shelf life, making them a reliable choice for manufacturers who require consistent performance over time. On the other hand, liquid intermediates are pre-dissolved solutions that are ready to use, offering convenience and time-saving benefits. They eliminate the need for additional mixing or preparation, which can be advantageous in high-volume production settings where efficiency is paramount. Liquid intermediates are often formulated to provide specific performance characteristics, such as enhanced throwing power or improved brightness, catering to the diverse needs of different applications. Both solid and liquid intermediates play a crucial role in the acid zinc plating process, each offering unique advantages that can be leveraged depending on the specific requirements of the application. The choice between solid and liquid intermediates often depends on factors such as the scale of production, the desired properties of the finished product, and the operational preferences of the manufacturer. For instance, in applications where precision and control are critical, such as in the electronics industry, liquid intermediates may be favored for their ability to deliver consistent results. Conversely, in large-scale industrial applications where cost-effectiveness and ease of handling are prioritized, solid intermediates may be the preferred option. The market for these intermediates is also influenced by trends in environmental regulations and sustainability, with manufacturers increasingly seeking products that minimize environmental impact while maintaining high performance standards. As a result, there is a growing emphasis on developing intermediates that are free from hazardous substances and that comply with stringent environmental standards. This shift towards more sustainable solutions is driving innovation in the market, with companies investing in research and development to create new formulations that meet the evolving needs of their customers. Overall, the solid and liquid segments of the Global Acid Zinc Plating Intermediate Market each offer distinct benefits and challenges, and their continued development is essential to supporting the diverse applications and industries that rely on acid zinc plating technology.

Automotive, Home Appliances, Consumer Electronics, Industrial Machinery, Others in the Global Acid Zinc Plating Intermediate Market:

The Global Acid Zinc Plating Intermediate Market finds extensive usage across various industries, each with its unique requirements and challenges. In the automotive industry, acid zinc plating is widely used to enhance the durability and corrosion resistance of metal components such as bolts, nuts, and fasteners. These components are critical to the safety and performance of vehicles, and the protective zinc coating helps to extend their lifespan and maintain their integrity under harsh environmental conditions. The demand for high-quality plating intermediates in this sector is driven by the need for reliable and long-lasting automotive parts that can withstand exposure to moisture, salt, and other corrosive elements. In the home appliances sector, acid zinc plating is used to improve the appearance and longevity of metal surfaces on products such as refrigerators, washing machines, and ovens. The plating process provides a smooth and shiny finish that enhances the aesthetic appeal of these appliances while also protecting them from rust and wear. This is particularly important in kitchen and laundry environments where appliances are frequently exposed to water and humidity. In the consumer electronics industry, acid zinc plating is employed to protect and enhance the performance of electronic components and connectors. The plating process ensures that these components maintain good electrical conductivity and resist corrosion, which is essential for the reliable operation of electronic devices. As consumer electronics continue to evolve and become more sophisticated, the demand for high-performance plating intermediates that can meet the stringent requirements of this industry is expected to grow. In the industrial machinery sector, acid zinc plating is used to protect metal parts and equipment from corrosion and wear, ensuring their efficient operation and longevity. This is particularly important in industries such as manufacturing, construction, and mining, where machinery is often exposed to harsh conditions and heavy use. The use of acid zinc plating intermediates in this sector helps to reduce maintenance costs and downtime, contributing to improved productivity and profitability. Finally, the "Others" category encompasses a wide range of applications, including the aerospace, marine, and telecommunications industries, where acid zinc plating is used to protect and enhance the performance of metal components. In these sectors, the demand for high-quality plating intermediates is driven by the need for reliable and durable products that can withstand challenging environments and meet strict regulatory standards. Overall, the Global Acid Zinc Plating Intermediate Market plays a crucial role in supporting the diverse needs of these industries, providing the essential materials and technologies needed to produce high-quality, corrosion-resistant metal products.

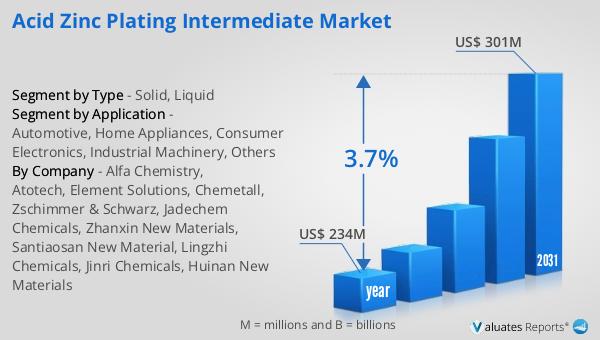

Global Acid Zinc Plating Intermediate Market Outlook:

The global market for Acid Zinc Plating Intermediate was valued at $234 million in 2024 and is anticipated to grow to a revised size of $301 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.7% over the forecast period. This growth trajectory underscores the increasing demand for acid zinc plating intermediates across various industries, driven by the need for enhanced corrosion resistance and aesthetic appeal in metal products. The market's expansion is supported by technological advancements and the development of new formulations that offer improved performance and environmental profiles. As industries continue to prioritize sustainability and efficiency, the demand for advanced plating intermediates that can meet these requirements is expected to rise. The projected growth also highlights the importance of acid zinc plating intermediates in supporting the manufacturing and maintenance of high-quality metal products, which are essential to the automotive, electronics, and industrial machinery sectors, among others. This market outlook reflects the dynamic nature of the industry, with ongoing innovation and adaptation to changing market conditions and regulatory requirements. As a result, companies operating in this space are likely to continue investing in research and development to create new solutions that address the evolving needs of their customers and contribute to the market's sustained growth.

| Report Metric | Details |

| Report Name | Acid Zinc Plating Intermediate Market |

| Accounted market size in year | US$ 234 million |

| Forecasted market size in 2031 | US$ 301 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Alfa Chemistry, Atotech, Element Solutions, Chemetall, Zschimmer & Schwarz, Jadechem Chemicals, Zhanxin New Materials, Santiaosan New Material, Lingzhi Chemicals, Jinri Chemicals, Huinan New Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |