What is Global Wafer Thinning Fluid Market?

The Global Wafer Thinning Fluid Market is a crucial segment within the semiconductor industry, focusing on the production and application of specialized fluids used in the wafer thinning process. Wafer thinning is an essential step in semiconductor manufacturing, where silicon wafers are reduced to a desired thickness to enhance their performance and integration into electronic devices. This process is vital for producing smaller, more efficient, and high-performing chips used in a wide range of electronic products, from smartphones to advanced computing systems. The market for wafer thinning fluids is driven by the increasing demand for miniaturized electronic components and the continuous advancements in semiconductor technology. These fluids are engineered to provide precise control over the thinning process, ensuring uniformity and reducing the risk of damage to the delicate wafers. As the semiconductor industry continues to evolve, the demand for high-quality wafer thinning fluids is expected to grow, supporting the development of next-generation electronic devices and contributing to the overall advancement of technology.

Acidic Material, Alkaline Material in the Global Wafer Thinning Fluid Market:

In the Global Wafer Thinning Fluid Market, acidic and alkaline materials play a pivotal role in the thinning process of semiconductor wafers. Acidic materials, often composed of chemicals like hydrofluoric acid, are used for their ability to etch silicon and other materials effectively. These acids are crucial in removing unwanted layers from the wafer surface, ensuring a smooth and uniform finish. The use of acidic materials is particularly important in achieving the desired wafer thickness, which is essential for the performance and reliability of semiconductor devices. On the other hand, alkaline materials, typically containing compounds like potassium hydroxide, offer a different approach to wafer thinning. Alkaline solutions are known for their selective etching properties, allowing for precise control over the thinning process. This precision is vital in applications where specific patterns or structures need to be maintained on the wafer surface. The choice between acidic and alkaline materials depends on various factors, including the type of wafer, the desired thickness, and the specific requirements of the semiconductor device being manufactured. Both acidic and alkaline materials have their advantages and limitations, and manufacturers often choose the appropriate fluid based on the specific needs of their production processes. The development and optimization of these materials are ongoing, with researchers and manufacturers continuously seeking ways to improve their effectiveness and reduce any potential environmental impact. As the demand for advanced semiconductor devices grows, the role of acidic and alkaline materials in the wafer thinning process will remain critical, driving innovation and efficiency in the Global Wafer Thinning Fluid Market.

200 mm, 300 mm, Others in the Global Wafer Thinning Fluid Market:

The Global Wafer Thinning Fluid Market finds its application across various wafer sizes, including 200 mm, 300 mm, and others, each serving different segments of the semiconductor industry. The 200 mm wafers are commonly used in the production of a wide range of semiconductor devices, including microcontrollers, sensors, and power management chips. These wafers are often employed in applications where cost-effectiveness and reliability are prioritized. The use of wafer thinning fluids in the 200 mm segment is crucial for achieving the desired thickness and ensuring the performance of the final product. The 300 mm wafers, on the other hand, are primarily used in the manufacturing of high-performance semiconductor devices, such as processors and memory chips. The larger size of these wafers allows for the production of more chips per wafer, increasing efficiency and reducing costs. The application of wafer thinning fluids in the 300 mm segment is essential for maintaining the structural integrity of the wafers and ensuring the quality of the final semiconductor devices. In addition to the 200 mm and 300 mm segments, the Global Wafer Thinning Fluid Market also caters to other wafer sizes, which are used in specialized applications. These may include wafers used in advanced research and development projects or in the production of niche semiconductor devices. The versatility of wafer thinning fluids allows them to be adapted to various wafer sizes and applications, making them an indispensable component of the semiconductor manufacturing process. As the demand for diverse semiconductor devices continues to grow, the application of wafer thinning fluids across different wafer sizes will remain a key factor in the advancement of the Global Wafer Thinning Fluid Market.

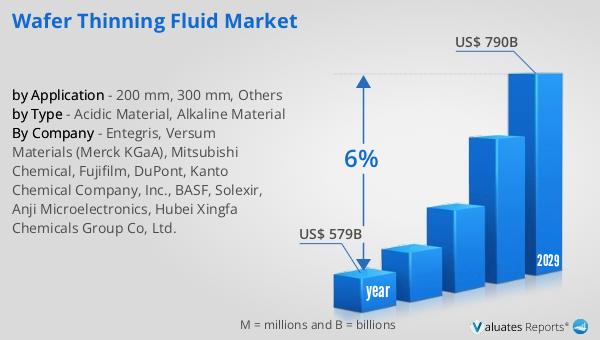

Global Wafer Thinning Fluid Market Outlook:

The semiconductor industry is experiencing significant growth, with the global market valued at approximately $579 billion in 2022. This market is projected to expand to $790 billion by 2029, reflecting a compound annual growth rate (CAGR) of 6% over the forecast period. This growth is driven by the increasing demand for advanced electronic devices, the proliferation of the Internet of Things (IoT), and the continuous advancements in semiconductor technology. The expansion of the semiconductor market is expected to have a positive impact on the Global Wafer Thinning Fluid Market, as the demand for high-quality wafer thinning fluids will increase in tandem with the growth of the semiconductor industry. The need for smaller, more efficient, and high-performing semiconductor devices is driving the development of innovative wafer thinning fluids that can meet the stringent requirements of modern manufacturing processes. As the semiconductor market continues to evolve, the Global Wafer Thinning Fluid Market is poised to play a crucial role in supporting the production of next-generation electronic devices, contributing to the overall advancement of technology and the global economy.

| Report Metric | Details |

| Report Name | Wafer Thinning Fluid Market |

| Accounted market size in year | US$ 579 billion |

| Forecasted market size in 2029 | US$ 790 billion |

| CAGR | 6% |

| Base Year | year |

| Forecasted years | 2025 - 2029 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Entegris, Versum Materials (Merck KGaA), Mitsubishi Chemical, Fujifilm, DuPont, Kanto Chemical Company, Inc., BASF, Solexir, Anji Microelectronics, Hubei Xingfa Chemicals Group Co, Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |