What is Global Sintered Silver Pastes Market?

The Global Sintered Silver Pastes Market is a specialized segment within the broader materials market, focusing on the production and application of sintered silver pastes. These pastes are primarily composed of silver particles that are used in various high-tech applications due to their excellent thermal and electrical conductivity. The sintering process involves heating the silver particles to a temperature below their melting point, causing them to bond together. This results in a dense, conductive layer that is ideal for use in electronic devices, power modules, and other advanced technologies. The demand for sintered silver pastes is driven by the growing need for efficient thermal management solutions in electronics, as well as the push for miniaturization and enhanced performance in electronic components. As industries continue to innovate and develop more sophisticated technologies, the role of sintered silver pastes becomes increasingly critical, making this market a key area of interest for manufacturers and researchers alike. The market is characterized by ongoing advancements in paste formulations and sintering techniques, aimed at improving the performance and reliability of the final products.

Pressure Sintering, Non-pressure Sintering in the Global Sintered Silver Pastes Market:

Pressure sintering and non-pressure sintering are two distinct methods used in the Global Sintered Silver Pastes Market, each with its own set of advantages and applications. Pressure sintering, also known as hot pressing, involves applying both heat and pressure to the silver paste. This method enhances the densification process, resulting in a more compact and robust final product. The application of pressure helps in reducing the porosity of the sintered layer, which in turn improves its mechanical strength and thermal conductivity. This makes pressure sintering particularly suitable for applications where high reliability and performance are critical, such as in power electronics and high-frequency devices. The process typically requires specialized equipment to apply uniform pressure and heat, making it a more complex and costly option compared to non-pressure sintering. However, the benefits in terms of product performance often justify the additional investment. On the other hand, non-pressure sintering, sometimes referred to as free sintering, relies solely on heat to achieve the bonding of silver particles. This method is generally simpler and more cost-effective, as it does not require the application of external pressure. Non-pressure sintering is suitable for applications where the mechanical strength of the sintered layer is less critical, or where cost considerations are a primary concern. The process involves heating the silver paste to a temperature that allows the particles to bond through diffusion, resulting in a conductive layer. While non-pressure sintering may not achieve the same level of densification as pressure sintering, it is still capable of producing high-quality conductive layers that meet the requirements of many electronic applications. Both pressure and non-pressure sintering have their place in the Global Sintered Silver Pastes Market, with the choice between the two often depending on the specific requirements of the application. For instance, in applications where thermal management is a priority, such as in LED modules or power semiconductors, pressure sintering may be preferred due to its superior thermal conductivity. Conversely, for applications where cost is a significant factor, such as in consumer electronics, non-pressure sintering may be more appropriate. The ongoing development of new sintering techniques and materials continues to expand the possibilities for both methods, allowing manufacturers to tailor their processes to meet the evolving demands of the market. As the industry progresses, the distinction between pressure and non-pressure sintering may become less pronounced, with hybrid approaches and innovative technologies blurring the lines between the two.

Electronics Devices, Piezoelectric Components, Electrodes of Displays, Others in the Global Sintered Silver Pastes Market:

The Global Sintered Silver Pastes Market finds extensive usage across various sectors, particularly in electronics devices, piezoelectric components, electrodes of displays, and other applications. In the realm of electronic devices, sintered silver pastes are crucial due to their exceptional electrical and thermal conductivity. They are often used in the assembly of power modules, where efficient heat dissipation is essential to maintain performance and reliability. The ability of sintered silver pastes to form strong, conductive bonds makes them ideal for use in high-power and high-frequency applications, such as inverters and converters used in renewable energy systems and electric vehicles. The miniaturization trend in electronics further amplifies the demand for these pastes, as they enable the creation of smaller, more efficient components without compromising on performance. In piezoelectric components, sintered silver pastes play a vital role in enhancing the performance of devices that rely on the piezoelectric effect, such as sensors, actuators, and transducers. The pastes are used to create conductive pathways that facilitate the efficient transfer of electrical signals, thereby improving the sensitivity and responsiveness of piezoelectric devices. This is particularly important in applications like medical ultrasound equipment and precision instrumentation, where accuracy and reliability are paramount. The use of sintered silver pastes in these components helps to ensure consistent performance, even under demanding conditions. For electrodes of displays, sintered silver pastes offer a reliable solution for creating conductive layers that are essential for the operation of various types of displays, including LCDs and OLEDs. The pastes provide excellent adhesion and conductivity, which are critical for the efficient functioning of display electrodes. This is especially important in high-resolution displays, where precise control of electrical signals is necessary to achieve the desired image quality. The use of sintered silver pastes in display electrodes helps to enhance the overall performance and longevity of the displays, making them a preferred choice for manufacturers seeking to deliver high-quality visual experiences. Beyond these specific applications, the versatility of sintered silver pastes allows them to be used in a wide range of other areas. This includes applications in the automotive industry, where they are used in the production of sensors and control units, as well as in the aerospace sector, where their high thermal and electrical conductivity are leveraged in various electronic systems. The adaptability of sintered silver pastes to different requirements and environments underscores their importance in the modern technological landscape. As industries continue to push the boundaries of innovation, the role of sintered silver pastes in enabling new possibilities and enhancing existing technologies remains a key driver of their market growth.

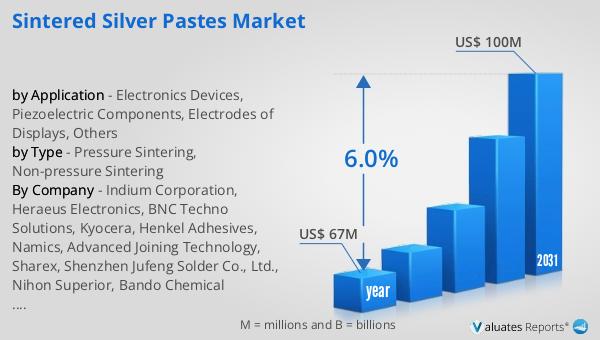

Global Sintered Silver Pastes Market Outlook:

In 2024, the global market for Sintered Silver Pastes was valued at approximately 67 million US dollars. Looking ahead, this market is anticipated to expand significantly, reaching an estimated size of 100 million US dollars by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.0% over the forecast period. The increasing demand for sintered silver pastes is largely driven by their critical role in enhancing the performance and reliability of electronic components. As industries such as electronics, automotive, and renewable energy continue to evolve, the need for advanced materials that offer superior thermal and electrical conductivity becomes more pronounced. Sintered silver pastes, with their unique properties, are well-positioned to meet these demands, making them an essential component in the development of next-generation technologies. The projected growth of the market reflects the ongoing advancements in paste formulations and sintering techniques, which are continually improving the performance and applicability of these materials. As a result, manufacturers and researchers are increasingly focusing on the development of innovative solutions that leverage the benefits of sintered silver pastes, further driving the market's expansion.

| Report Metric | Details |

| Report Name | Sintered Silver Pastes Market |

| Accounted market size in year | US$ 67 million |

| Forecasted market size in 2031 | US$ 100 million |

| CAGR | 6.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Indium Corporation, Heraeus Electronics, BNC Techno Solutions, Kyocera, Henkel Adhesives, Namics, Advanced Joining Technology, Sharex, Shenzhen Jufeng Solder Co., Ltd., Nihon Superior, Bando Chemical Industries, Taiyo Holdings, Aritech Chemazone |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |