What is Global Screw Doser Market?

The Global Screw Doser Market is a specialized segment within the broader industrial machinery and equipment sector, focusing on devices designed to precisely measure and dispense materials. These machines are essential in various industries, including pharmaceuticals, chemicals, food processing, and plastics, where accurate dosing of materials is crucial for product quality and consistency. Screw dosers use a rotating screw mechanism to control the flow of materials, ensuring precise measurement and delivery. This market is driven by the increasing demand for automation and precision in manufacturing processes, as well as the need for efficient handling of bulk materials. The global market for screw dosers is characterized by technological advancements, with manufacturers continually innovating to improve accuracy, efficiency, and ease of use. As industries strive for greater efficiency and reduced waste, the demand for reliable and precise dosing solutions like screw dosers is expected to grow.

Volumetric Screw Doser, Gravimetric Screw Doser in the Global Screw Doser Market:

Volumetric and gravimetric screw dosers are two primary types of dosing systems used in the Global Screw Doser Market, each with distinct functionalities and applications. Volumetric screw dosers operate by measuring the volume of material dispensed, using a rotating screw to deliver a consistent volume of material per revolution. This type of doser is typically used in applications where the density of the material is consistent, as it relies on volume rather than weight for measurement. Volumetric dosers are often favored for their simplicity, cost-effectiveness, and ease of maintenance. They are suitable for applications where high precision is not critical, and the material's bulk density remains stable. On the other hand, gravimetric screw dosers measure the weight of the material being dispensed, providing a higher level of accuracy and precision. These systems use load cells to weigh the material as it is dispensed, adjusting the screw speed to ensure the correct weight is delivered. Gravimetric dosers are ideal for applications where precision is paramount, such as in the pharmaceutical and food industries, where even slight variations in material weight can impact product quality. They are also beneficial in situations where the material's density may vary, as they provide a more accurate measurement by weight rather than volume. The choice between volumetric and gravimetric screw dosers depends on several factors, including the required level of precision, the nature of the material being dosed, and the specific application requirements. In industries where precision and consistency are critical, gravimetric dosers are often preferred despite their higher cost and complexity. However, in applications where cost is a significant consideration and precision requirements are less stringent, volumetric dosers offer a practical and efficient solution. Both types of dosers play a crucial role in the Global Screw Doser Market, catering to the diverse needs of industries seeking reliable and efficient dosing solutions. As technology continues to advance, the capabilities of both volumetric and gravimetric dosers are expected to improve, offering even greater accuracy, efficiency, and ease of use.

Fine Granular Products, Low Density Powders in the Global Screw Doser Market:

The Global Screw Doser Market finds extensive application in handling fine granular products and low-density powders, two categories of materials that require precise dosing for optimal processing and product quality. Fine granular products, such as sugar, salt, and certain chemicals, demand accurate dosing to ensure consistency in product formulation and quality. Screw dosers are particularly well-suited for these materials, as their rotating screw mechanism allows for precise control over the flow and measurement of granular materials. This precision is crucial in industries like food processing and pharmaceuticals, where even minor deviations in ingredient quantities can significantly impact the final product. The ability of screw dosers to handle fine granular products with high accuracy makes them indispensable in these sectors, where quality and consistency are paramount. Similarly, low-density powders, such as flour, talc, and certain pharmaceutical ingredients, also benefit from the precise dosing capabilities of screw dosers. These materials often present challenges in handling and dosing due to their low bulk density and tendency to become airborne. Screw dosers address these challenges by providing a controlled and enclosed environment for dosing, minimizing dust generation and ensuring accurate measurement. In the pharmaceutical industry, for example, the precise dosing of low-density powders is critical for ensuring the correct dosage of active ingredients in medications. Screw dosers offer the accuracy and reliability needed to meet these stringent requirements, making them a preferred choice for pharmaceutical manufacturers. Additionally, in the chemical industry, where low-density powders are often used in formulations, screw dosers provide the precision and control necessary to achieve the desired product characteristics. The versatility of screw dosers in handling both fine granular products and low-density powders underscores their importance in the Global Screw Doser Market. As industries continue to demand higher levels of precision and efficiency in material handling, the role of screw dosers in these applications is expected to grow, driven by ongoing advancements in technology and automation.

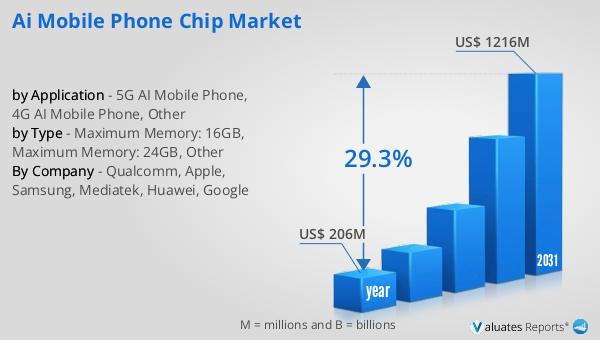

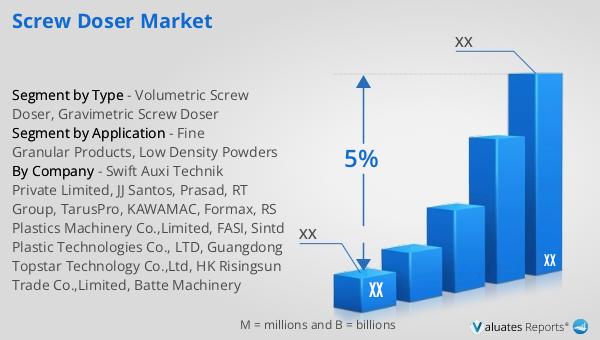

Global Screw Doser Market Outlook:

In 2022, the global pharmaceutical market reached a valuation of 1,475 billion USD, reflecting its significant size and influence within the global economy. This market is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years, indicating steady expansion driven by factors such as increasing healthcare needs, technological advancements, and rising investments in research and development. In contrast, the chemical drug market, a subset of the broader pharmaceutical sector, has shown a different growth trajectory. From 2018 to 2022, the chemical drug market expanded from 1,005 billion USD to 1,094 billion USD. This growth, while positive, suggests a more moderate pace compared to the overall pharmaceutical market. The differences in growth rates between these two markets can be attributed to various factors, including the increasing focus on biologics and personalized medicine within the pharmaceutical industry, which may be outpacing traditional chemical drug development. Despite these differences, both markets remain integral to the healthcare landscape, with the chemical drug market continuing to play a crucial role in providing essential medications to patients worldwide. As the global healthcare environment evolves, the interplay between these markets will likely shape future trends and innovations in the pharmaceutical industry.

| Report Metric | Details |

| Report Name | Screw Doser Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Swift Auxi Technik Private Limited, JJ Santos, Prasad, RT Group, TarusPro, KAWAMAC, Formax, RS Plastics Machinery Co.,Limited, FASI, Sintd Plastic Technologies Co., LTD, Guangdong Topstar Technology Co.,Ltd, HK Risingsun Trade Co.,Limited, Batte Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |