What is Global Pharmaceutical Intermediate Bulk Container (IBC) Market?

The Global Pharmaceutical Intermediate Bulk Container (IBC) Market is a crucial segment within the pharmaceutical industry, focusing on the storage and transportation of bulk materials. These containers are designed to handle large quantities of pharmaceutical ingredients, ensuring they are stored safely and transported efficiently. IBCs are essential for maintaining the integrity and quality of pharmaceutical products, as they provide a controlled environment that protects against contamination and degradation. The market for these containers is driven by the increasing demand for pharmaceuticals worldwide, as well as the need for efficient and cost-effective storage solutions. IBCs are available in various materials, including stainless steel and polyethylene, each offering unique benefits depending on the specific requirements of the pharmaceutical product. The versatility and reliability of IBCs make them an indispensable component in the pharmaceutical supply chain, supporting the industry's growth and ensuring the safe delivery of medicines to consumers. As the pharmaceutical industry continues to expand, the demand for high-quality IBCs is expected to rise, highlighting their importance in the global market.

Stainless Steel IBCs, Polyethylene IBCs in the Global Pharmaceutical Intermediate Bulk Container (IBC) Market:

Stainless Steel IBCs are a popular choice in the Global Pharmaceutical Intermediate Bulk Container (IBC) Market due to their durability and resistance to corrosion. These containers are ideal for storing and transporting sensitive pharmaceutical ingredients that require a high level of protection. Stainless steel IBCs are known for their strength and longevity, making them a cost-effective solution for pharmaceutical companies looking to invest in long-term storage options. They are easy to clean and sanitize, which is crucial in maintaining the purity and quality of pharmaceutical products. Additionally, stainless steel IBCs can withstand extreme temperatures and harsh environmental conditions, ensuring the safe transport of pharmaceuticals across various regions. On the other hand, Polyethylene IBCs offer a lightweight and flexible alternative to stainless steel containers. These IBCs are made from high-density polyethylene, a material known for its chemical resistance and durability. Polyethylene IBCs are particularly suitable for storing and transporting liquid pharmaceuticals, as they provide a leak-proof solution that prevents contamination. They are also more affordable than stainless steel IBCs, making them an attractive option for companies with budget constraints. Despite their lower cost, polyethylene IBCs still offer a high level of protection for pharmaceutical products, ensuring they remain safe and effective throughout the supply chain. Both stainless steel and polyethylene IBCs play a vital role in the pharmaceutical industry, providing reliable and efficient storage solutions that meet the diverse needs of pharmaceutical companies. The choice between these two types of IBCs often depends on the specific requirements of the pharmaceutical product, as well as the company's budget and logistical considerations. As the demand for pharmaceuticals continues to grow, the need for high-quality IBCs will remain a critical factor in ensuring the safe and efficient delivery of medicines to consumers worldwide.

Tablet & Capsules, Powders, Ointments, Others in the Global Pharmaceutical Intermediate Bulk Container (IBC) Market:

The usage of Global Pharmaceutical Intermediate Bulk Container (IBC) Market extends to various pharmaceutical forms, including tablets and capsules, powders, ointments, and others. In the case of tablets and capsules, IBCs are used to store and transport the bulk ingredients required for their production. These containers ensure that the ingredients remain free from contamination and degradation, maintaining their efficacy and safety. The controlled environment provided by IBCs is essential for preserving the quality of these pharmaceutical forms, which are often sensitive to environmental factors such as humidity and temperature. For powders, IBCs offer a secure and efficient solution for handling large quantities of these materials. The containers prevent the powders from becoming airborne, reducing the risk of contamination and ensuring the safety of workers handling these substances. IBCs also facilitate the easy transfer of powders during the manufacturing process, streamlining production and reducing waste. When it comes to ointments, IBCs provide a hygienic and controlled environment for storing and transporting these semi-solid pharmaceutical forms. The containers protect the ointments from contamination and degradation, ensuring they remain effective and safe for use. IBCs also allow for the easy dispensing of ointments during the manufacturing process, improving efficiency and reducing the risk of contamination. In addition to these specific pharmaceutical forms, IBCs are also used for other applications within the pharmaceutical industry, such as the storage and transport of liquid pharmaceuticals and active pharmaceutical ingredients (APIs). The versatility and reliability of IBCs make them an essential component in the pharmaceutical supply chain, supporting the industry's growth and ensuring the safe delivery of medicines to consumers. As the demand for pharmaceuticals continues to rise, the need for high-quality IBCs will remain a critical factor in ensuring the safe and efficient delivery of medicines to consumers worldwide.

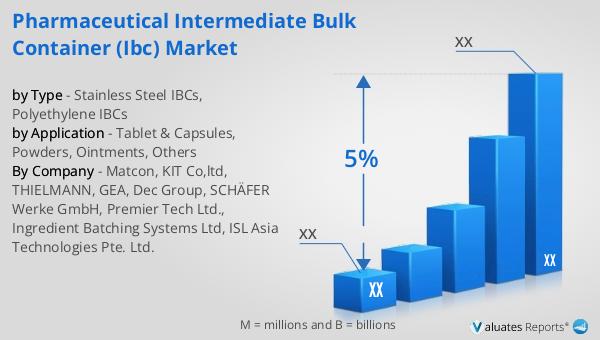

Global Pharmaceutical Intermediate Bulk Container (IBC) Market Outlook:

The outlook for the Global Pharmaceutical Intermediate Bulk Container (IBC) Market is closely tied to the broader pharmaceutical market, which was valued at 1,475 billion USD in 2022. This market is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years. In comparison, the chemical drug market has shown a steady increase, rising from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth in the pharmaceutical and chemical drug markets underscores the increasing demand for efficient storage and transportation solutions, such as IBCs, to support the industry's expansion. As pharmaceutical companies continue to innovate and develop new products, the need for reliable and versatile IBCs will become even more critical. These containers play a vital role in ensuring the safe and efficient delivery of pharmaceutical products to consumers, supporting the industry's growth and contributing to the overall health and well-being of people worldwide. The continued expansion of the pharmaceutical market highlights the importance of investing in high-quality IBCs to meet the growing demand for medicines and ensure their safe and effective delivery to consumers.

| Report Metric | Details |

| Report Name | Pharmaceutical Intermediate Bulk Container (IBC) Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Matcon, KIT Co,ltd, THIELMANN, GEA, Dec Group, SCHÄFER Werke GmbH, Premier Tech Ltd., Ingredient Batching Systems Ltd, ISL Asia Technologies Pte. Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |