What is Global Pharma Grade Resins Market?

The Global Pharma Grade Resins Market is a specialized segment within the broader pharmaceutical industry, focusing on the production and application of high-quality resins used in drug formulation and delivery. These resins are essential components in the pharmaceutical manufacturing process, serving as excipients that enhance the stability, efficacy, and delivery of active pharmaceutical ingredients (APIs). They are designed to meet stringent regulatory standards, ensuring safety and effectiveness in medical applications. The market encompasses a variety of resin types, including ion exchange resins, which are pivotal in drug purification and separation processes. The demand for pharma grade resins is driven by the growing pharmaceutical industry, advancements in drug delivery systems, and the increasing need for innovative drug formulations. As the pharmaceutical sector continues to expand globally, the role of pharma grade resins becomes increasingly significant, offering solutions that improve drug solubility, bioavailability, and patient compliance. These resins are integral to the development of various dosage forms, including tablets, capsules, and liquid formulations, making them indispensable in modern medicine. The market is characterized by continuous innovation, with manufacturers investing in research and development to create resins that meet the evolving needs of the pharmaceutical industry.

Anion Exchange Resin, Cation Exchange Resin in the Global Pharma Grade Resins Market:

Anion exchange resins and cation exchange resins are two critical components of the Global Pharma Grade Resins Market, each serving distinct functions in pharmaceutical applications. Anion exchange resins are polymers that facilitate the exchange of negatively charged ions, or anions, in a solution. These resins are particularly valuable in the purification and separation of pharmaceutical compounds, as they can selectively bind and remove unwanted anions from a mixture, thereby enhancing the purity and quality of the final product. In drug formulation, anion exchange resins are used to improve the stability and solubility of active pharmaceutical ingredients (APIs), making them more effective in delivering therapeutic benefits. They are also employed in controlled release formulations, where they help regulate the release rate of drugs, ensuring a sustained therapeutic effect over time. On the other hand, cation exchange resins are designed to exchange positively charged ions, or cations, in a solution. These resins play a crucial role in the pharmaceutical industry by facilitating the removal of metal ions and other impurities from drug formulations. Cation exchange resins are often used in the production of oral dosage forms, where they enhance the taste and stability of medications. They are also instrumental in the development of ion-exchange chromatography techniques, which are used to separate and purify complex mixtures of pharmaceutical compounds. Both anion and cation exchange resins are essential in the formulation of various drug delivery systems, including tablets, capsules, and liquid formulations. They contribute to the overall efficacy and safety of pharmaceutical products by ensuring that the active ingredients are delivered in a controlled and predictable manner. The use of these resins in drug formulation is driven by the need for improved drug solubility, bioavailability, and patient compliance. As the pharmaceutical industry continues to evolve, the demand for high-quality anion and cation exchange resins is expected to grow, driven by the increasing complexity of drug formulations and the need for innovative drug delivery solutions. Manufacturers in the Global Pharma Grade Resins Market are investing in research and development to create resins that meet the specific needs of pharmaceutical companies, ensuring that they remain at the forefront of innovation in drug formulation and delivery.

Suspension, Dispersible Tablets, Lozenges, Chewing Gums in the Global Pharma Grade Resins Market:

The Global Pharma Grade Resins Market plays a vital role in the development and production of various pharmaceutical dosage forms, including suspensions, dispersible tablets, lozenges, and chewing gums. In the formulation of suspensions, pharma grade resins are used as stabilizing agents that prevent the settling of solid particles in a liquid medium. These resins enhance the stability and uniformity of suspensions, ensuring that the active pharmaceutical ingredients (APIs) are evenly distributed throughout the liquid. This is crucial for maintaining the efficacy and safety of the medication, as it ensures that patients receive the correct dosage with each administration. In dispersible tablets, pharma grade resins are employed to improve the disintegration and dissolution properties of the tablets. These resins facilitate the rapid breakdown of the tablet in water, allowing for easy administration and absorption of the active ingredients. This is particularly beneficial for patients who have difficulty swallowing traditional tablets, as dispersible tablets can be dissolved in water before consumption. In the production of lozenges, pharma grade resins are used to enhance the taste and texture of the final product. These resins help mask the bitter taste of certain APIs, making the lozenges more palatable for patients. They also contribute to the controlled release of the active ingredients, ensuring a sustained therapeutic effect as the lozenge dissolves in the mouth. In the formulation of chewing gums, pharma grade resins are used as binding agents that provide the desired texture and consistency. These resins help maintain the structural integrity of the gum while allowing for the gradual release of the active ingredients during chewing. This is particularly useful for delivering medications that require prolonged contact with the oral mucosa for optimal absorption. Overall, the use of pharma grade resins in these dosage forms enhances the effectiveness, safety, and patient compliance of pharmaceutical products. As the demand for innovative drug delivery systems continues to grow, the role of pharma grade resins in the development of suspensions, dispersible tablets, lozenges, and chewing gums is expected to become increasingly important.

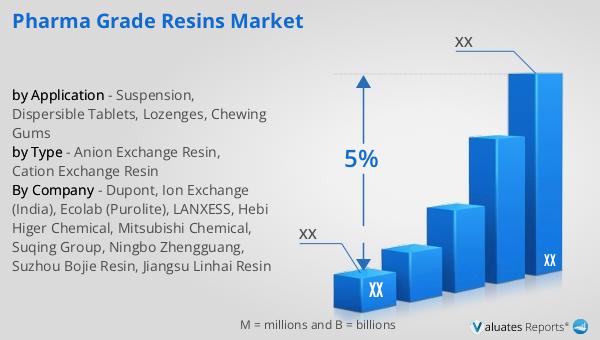

Global Pharma Grade Resins Market Outlook:

The outlook for the Global Pharma Grade Resins Market is closely tied to the broader trends in the pharmaceutical industry. In 2022, the global pharmaceutical market was valued at approximately 1,475 billion USD, with a projected compound annual growth rate (CAGR) of 5% over the next six years. This growth is indicative of the increasing demand for pharmaceutical products and the continuous innovation in drug development and delivery systems. In comparison, the chemical drug market, which is a subset of the pharmaceutical industry, was estimated to grow from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth reflects the ongoing advancements in chemical drug formulations and the rising need for effective and safe medications. The Global Pharma Grade Resins Market is expected to benefit from these trends, as the demand for high-quality resins used in drug formulation and delivery continues to rise. As pharmaceutical companies strive to develop more effective and patient-friendly medications, the role of pharma grade resins in enhancing drug solubility, bioavailability, and stability becomes increasingly important. The market is characterized by continuous innovation, with manufacturers investing in research and development to create resins that meet the evolving needs of the pharmaceutical industry. As a result, the Global Pharma Grade Resins Market is poised for growth, driven by the expanding pharmaceutical industry and the increasing complexity of drug formulations.

| Report Metric | Details |

| Report Name | Pharma Grade Resins Market |

| CAGR | 5% |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dupont, Ion Exchange (India), Ecolab (Purolite), LANXESS, Hebi Higer Chemical, Mitsubishi Chemical, Suqing Group, Ningbo Zhengguang, Suzhou Bojie Resin, Jiangsu Linhai Resin |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |