What is Global Metal Thermal Spray Wires Market?

The Global Metal Thermal Spray Wires Market is a specialized segment within the broader thermal spray coatings industry, focusing on the use of metal wires to create protective and functional coatings on various surfaces. These wires are melted and sprayed onto surfaces to enhance their properties, such as resistance to wear, corrosion, and heat. The market is driven by the increasing demand for durable and efficient coatings in industries like aerospace, automotive, and energy. Metal thermal spray wires are preferred for their ability to provide high-quality coatings that extend the lifespan of components and reduce maintenance costs. The market encompasses a wide range of metal types, including pure metals and metal alloys, each offering unique benefits depending on the application. As industries continue to seek advanced materials to improve performance and sustainability, the Global Metal Thermal Spray Wires Market is expected to grow, driven by technological advancements and the need for high-performance coatings in critical applications. The market's growth is also supported by the rising awareness of the benefits of thermal spray coatings, such as improved efficiency and reduced environmental impact, making it an essential component of modern industrial processes.

Pure Metal Thermal Spray Wires, Metal Alloy Thermal Spray Wires in the Global Metal Thermal Spray Wires Market:

Pure Metal Thermal Spray Wires and Metal Alloy Thermal Spray Wires are two primary categories within the Global Metal Thermal Spray Wires Market, each serving distinct purposes and offering unique advantages. Pure Metal Thermal Spray Wires are composed of a single metal element, such as aluminum, zinc, or copper, and are used for applications where the specific properties of the pure metal are desired. For instance, aluminum wires are often used for corrosion protection due to their excellent resistance to oxidation, while zinc wires are commonly applied in galvanizing processes to protect steel structures from rust. Copper wires, on the other hand, are valued for their electrical conductivity and are used in applications requiring efficient heat and electricity transfer. These pure metal wires are typically chosen for their inherent properties, which can be enhanced through the thermal spray process to meet specific industrial needs.

Aerospace & Defense, Oil & Gas, Pipeline, Machine Tools, Automotive & Transport, Power Generation, Others in the Global Metal Thermal Spray Wires Market:

Metal Alloy Thermal Spray Wires, in contrast, are composed of a combination of two or more metals, creating an alloy with properties that are superior to those of the individual metals. These alloys are engineered to provide enhanced performance characteristics, such as increased hardness, wear resistance, and thermal stability. Common metal alloys used in thermal spray wires include stainless steel, nickel-chromium, and cobalt-based alloys. Stainless steel wires are widely used in applications requiring high corrosion resistance and mechanical strength, making them ideal for harsh environments like marine and chemical processing industries. Nickel-chromium alloys are known for their excellent high-temperature performance and are often used in aerospace and power generation applications where components are exposed to extreme heat. Cobalt-based alloys, with their exceptional wear resistance and ability to withstand high temperatures, are used in demanding applications such as turbine blades and engine components.

Global Metal Thermal Spray Wires Market Outlook:

The choice between pure metal and metal alloy thermal spray wires depends on the specific requirements of the application, including the desired properties of the coating, the operating environment, and the cost considerations. Pure metal wires are generally more cost-effective and are suitable for applications where the unique properties of the metal are sufficient to meet the performance requirements. Metal alloy wires, while typically more expensive, offer superior performance characteristics and are chosen for applications where enhanced durability and resistance to extreme conditions are critical. The Global Metal Thermal Spray Wires Market continues to evolve as new materials and technologies are developed, offering industries a wide range of options to improve the performance and longevity of their components. As industries face increasing pressure to enhance efficiency and reduce environmental impact, the demand for advanced thermal spray coatings is expected to grow, driving innovation and expansion in the market.

| Report Metric | Details |

| Report Name | Metal Thermal Spray Wires Market |

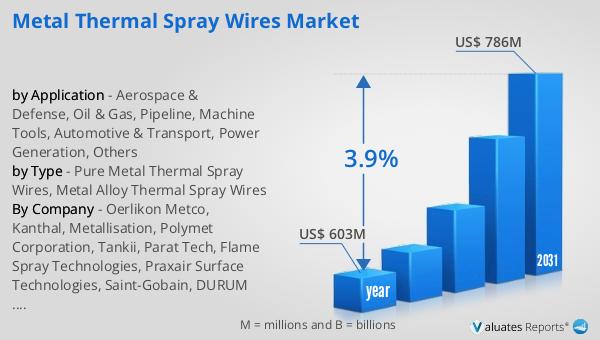

| Accounted market size in year | US$ 603 million |

| Forecasted market size in 2031 | US$ 786 million |

| CAGR | 3.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Oerlikon Metco, Kanthal, Metallisation, Polymet Corporation, Tankii, Parat Tech, Flame Spray Technologies, Praxair Surface Technologies, Saint-Gobain, DURUM VERSCHLEISS-SCHUTZ, Corodur Fülldraht, Plasma Powders & Systems, United Coatings Technology, HAI Inc, Thermion, WL Allotech, Wintwire |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |