What is Global Medical Grade Acetal Copolymer Market?

The Global Medical Grade Acetal Copolymer Market is a specialized segment within the broader polymer industry, focusing on the production and application of acetal copolymers specifically designed for medical use. Acetal copolymers, also known as polyoxymethylene (POM), are engineering thermoplastics known for their high strength, rigidity, and excellent dimensional stability. These properties make them ideal for manufacturing medical devices and components that require precision and durability. The medical grade variant of acetal copolymer is formulated to meet stringent biocompatibility standards, ensuring it is safe for use in medical applications. This market is driven by the increasing demand for high-performance materials in the healthcare sector, where reliability and safety are paramount. The versatility of medical grade acetal copolymer allows it to be used in a wide range of applications, from surgical instruments to drug delivery systems, making it an essential material in the medical device industry. As healthcare technology advances, the demand for materials that can meet the rigorous requirements of medical applications continues to grow, positioning the Global Medical Grade Acetal Copolymer Market as a critical component of the medical materials landscape.

Low Heat Resistant, Medium Heat Resistant, High Heat Resistan in the Global Medical Grade Acetal Copolymer Market:

In the Global Medical Grade Acetal Copolymer Market, heat resistance is a crucial factor that determines the suitability of the material for various medical applications. Acetal copolymers are categorized based on their heat resistance into three main types: low heat resistant, medium heat resistant, and high heat resistant. Low heat resistant acetal copolymers are typically used in applications where the material is not exposed to high temperatures. These applications might include components that are used in environments with minimal thermal stress, such as certain types of diagnostic devices or non-invasive medical tools. Despite their lower heat resistance, these copolymers still offer excellent mechanical properties and are often chosen for their cost-effectiveness and ease of processing. Medium heat resistant acetal copolymers are designed to withstand moderate temperatures, making them suitable for a wider range of medical applications. These materials can endure the heat generated during certain sterilization processes, which is essential for maintaining the sterility and safety of medical devices. They are often used in applications such as lancing devices and biosensor systems, where moderate heat resistance is necessary to ensure the device's functionality and longevity. High heat resistant acetal copolymers are engineered to perform under high-temperature conditions, making them ideal for applications that involve repeated sterilization or exposure to high heat. These copolymers are often used in autoinjectors and other drug delivery systems that require frequent sterilization to prevent contamination. The high heat resistance ensures that the material maintains its structural integrity and performance characteristics even after multiple sterilization cycles. This is particularly important in medical applications where device failure could have serious consequences for patient safety. The choice between low, medium, and high heat resistant acetal copolymers depends on the specific requirements of the medical application, including the expected temperature exposure and the need for sterilization. Manufacturers must carefully consider these factors when selecting materials for medical devices to ensure they meet the necessary safety and performance standards. As the medical device industry continues to evolve, the demand for acetal copolymers with varying levels of heat resistance is expected to grow, driven by the need for materials that can meet the diverse requirements of modern healthcare applications.

Autoinjectors, Diagnostic Devices, Lancing Devices, Biosensor Systems, Others in the Global Medical Grade Acetal Copolymer Market:

The Global Medical Grade Acetal Copolymer Market plays a significant role in the development and production of various medical devices, including autoinjectors, diagnostic devices, lancing devices, biosensor systems, and others. Autoinjectors are devices designed to deliver a specific dose of medication, often used for self-administration by patients. Medical grade acetal copolymers are ideal for these devices due to their strength, durability, and biocompatibility. The material's ability to withstand repeated use and sterilization processes ensures that autoinjectors remain reliable and safe for patients. In diagnostic devices, acetal copolymers are used for components that require precision and stability. These devices often involve intricate mechanisms that must function accurately to provide reliable diagnostic results. The dimensional stability and mechanical strength of acetal copolymers make them suitable for these applications, ensuring that diagnostic devices perform consistently over time. Lancing devices, used for obtaining small blood samples, also benefit from the properties of medical grade acetal copolymers. The material's rigidity and strength allow for the precise movement of the lancet, ensuring that the device functions effectively and safely. Additionally, the biocompatibility of acetal copolymers ensures that they do not cause adverse reactions when in contact with the skin. Biosensor systems, which detect and measure biological information, require materials that can maintain their performance in various environmental conditions. Acetal copolymers offer the necessary stability and durability, making them suitable for use in biosensor components. The material's resistance to moisture and chemicals ensures that biosensors remain accurate and reliable, even in challenging conditions. Beyond these specific applications, medical grade acetal copolymers are used in a wide range of other medical devices and components. Their versatility and performance characteristics make them a popular choice for manufacturers looking to produce high-quality, reliable medical products. As the demand for advanced medical devices continues to grow, the role of acetal copolymers in the medical industry is expected to expand, driven by the need for materials that can meet the rigorous demands of modern healthcare applications.

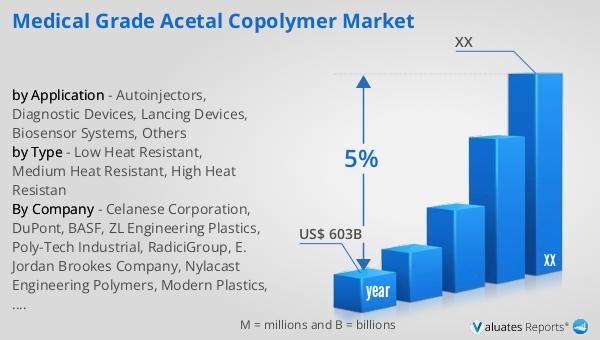

Global Medical Grade Acetal Copolymer Market Outlook:

Our research indicates that the global market for medical devices is projected to reach approximately $603 billion by the year 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including advancements in medical technology, an aging global population, and increasing healthcare expenditures. As medical devices become more sophisticated and integrated with digital technologies, the demand for high-quality materials like medical grade acetal copolymers is expected to rise. These materials are essential for manufacturing reliable and durable medical devices that meet the stringent safety and performance standards required in the healthcare industry. The steady growth of the medical device market presents significant opportunities for manufacturers and suppliers of medical grade acetal copolymers, as they play a crucial role in the development of innovative medical solutions. As the market continues to expand, companies that can provide high-performance materials that meet the evolving needs of the healthcare sector are likely to see increased demand for their products. This growth trajectory underscores the importance of investing in research and development to create advanced materials that can support the next generation of medical devices.

| Report Metric | Details |

| Report Name | Medical Grade Acetal Copolymer Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Celanese Corporation, DuPont, BASF, ZL Engineering Plastics, Poly-Tech Industrial, RadiciGroup, E. Jordan Brookes Company, Nylacast Engineering Polymers, Modern Plastics, Aetna Plastics, Polymer Plastics Company, Ensinger, Polyplastics, Alro Plastics, Acetal Copolymer, Dotmar NZ |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |