What is Global Medical Gas Ball Valves Market?

The Global Medical Gas Ball Valves Market is a specialized segment within the broader medical equipment industry, focusing on the production and distribution of ball valves specifically designed for medical gas systems. These valves play a crucial role in controlling the flow of medical gases such as oxygen, nitrous oxide, and carbon dioxide, which are essential for various medical procedures and patient care. The market is driven by the increasing demand for advanced healthcare facilities and the growing need for efficient and safe medical gas delivery systems. Medical gas ball valves are integral to ensuring the precise and reliable delivery of gases, which is vital for patient safety and the effectiveness of medical treatments. The market is characterized by technological advancements, stringent regulatory standards, and a focus on enhancing the safety and efficiency of medical gas systems. As healthcare infrastructure continues to expand globally, the demand for high-quality medical gas ball valves is expected to rise, making this market a critical component of the healthcare industry.

Copper, Brass in the Global Medical Gas Ball Valves Market:

Copper and brass are two primary materials used in the manufacturing of medical gas ball valves, each offering distinct advantages that cater to the specific needs of the Global Medical Gas Ball Valves Market. Copper is renowned for its excellent thermal and electrical conductivity, making it an ideal choice for applications where heat dissipation and electrical grounding are critical. In the context of medical gas systems, copper's natural antimicrobial properties are particularly beneficial, as they help reduce the risk of bacterial contamination in medical environments. This is crucial in healthcare settings where maintaining sterility and preventing infections are top priorities. Additionally, copper's durability and resistance to corrosion ensure that the valves have a long service life, even in demanding conditions. On the other hand, brass, an alloy of copper and zinc, offers a unique combination of strength, ductility, and corrosion resistance. Brass valves are known for their robustness and ability to withstand high pressures, making them suitable for use in medical gas systems that require reliable performance under varying conditions. The material's machinability also allows for precise manufacturing, ensuring that the valves meet the stringent standards required in medical applications. Furthermore, brass's aesthetic appeal and ease of maintenance make it a preferred choice for visible installations in healthcare facilities. Both copper and brass are recyclable materials, aligning with the growing emphasis on sustainability and environmental responsibility in the medical industry. The choice between copper and brass in the production of medical gas ball valves often depends on specific application requirements, cost considerations, and regulatory compliance. Manufacturers in the Global Medical Gas Ball Valves Market must carefully evaluate these factors to select the most appropriate material for their products. As the demand for advanced medical gas systems continues to grow, the use of copper and brass in valve manufacturing is expected to remain a key focus area, driving innovation and ensuring the delivery of safe and efficient healthcare solutions.

Carbon Dioxide Transport, Oxygen Transport, Other Medical Gas Transport in the Global Medical Gas Ball Valves Market:

The usage of Global Medical Gas Ball Valves Market in areas such as carbon dioxide transport, oxygen transport, and other medical gas transport is critical to the functioning of modern healthcare facilities. In carbon dioxide transport, medical gas ball valves are used to regulate the flow of CO2, which is often utilized in minimally invasive surgical procedures to inflate and stabilize body cavities, providing surgeons with a clear view of the surgical area. The precision and reliability of these valves are essential to maintaining the correct pressure and flow rate, ensuring patient safety and the success of the procedure. In oxygen transport, medical gas ball valves play a vital role in controlling the delivery of oxygen to patients, which is crucial for respiratory support in various medical situations, including surgeries, intensive care, and emergency response. The valves must ensure a consistent and uninterrupted flow of oxygen, as any disruption can have serious consequences for patient health. The design and material of the valves, often made from copper or brass, contribute to their ability to withstand the high pressures and demanding conditions associated with oxygen transport. In addition to carbon dioxide and oxygen, medical gas ball valves are used in the transport of other medical gases such as nitrous oxide, medical air, and helium. Each of these gases serves specific purposes in medical treatments and procedures, and the valves must be capable of handling the unique properties and requirements of each gas. For instance, nitrous oxide is commonly used as an anesthetic agent, and the valves must ensure precise control to maintain the desired level of sedation. Similarly, medical air is used in respiratory therapies and must be delivered at the correct pressure and flow rate to be effective. The versatility and reliability of medical gas ball valves make them indispensable components in the safe and efficient transport of these gases, supporting a wide range of medical applications and enhancing patient care.

Global Medical Gas Ball Valves Market Outlook:

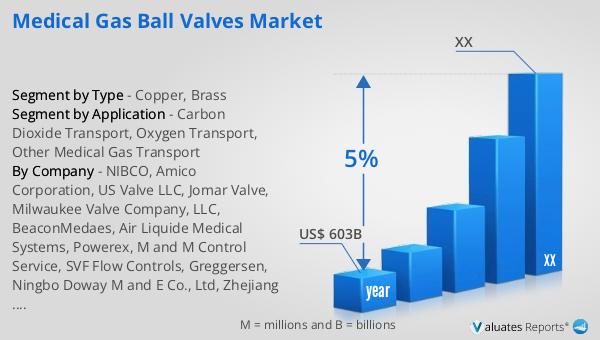

Based on our research, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth trajectory underscores the increasing demand for innovative medical technologies and devices that enhance patient care and improve healthcare outcomes. The expansion of the medical device market is driven by several factors, including advancements in technology, an aging global population, and the rising prevalence of chronic diseases. As healthcare systems worldwide strive to improve the quality and accessibility of care, the demand for medical devices that offer precision, efficiency, and safety continues to rise. The market's growth is also fueled by the increasing adoption of digital health solutions and the integration of artificial intelligence and machine learning in medical devices, which are transforming the way healthcare is delivered. Furthermore, the ongoing focus on personalized medicine and the development of minimally invasive surgical techniques are contributing to the market's expansion. As the medical device industry evolves, companies are investing in research and development to create innovative products that meet the changing needs of healthcare providers and patients. This dynamic market environment presents significant opportunities for growth and innovation, making it an exciting time for stakeholders in the medical device industry.

| Report Metric | Details |

| Report Name | Medical Gas Ball Valves Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | NIBCO, Amico Corporation, US Valve LLC, Jomar Valve, Milwaukee Valve Company, LLC, BeaconMedaes, Air Liquide Medical Systems, Powerex, M and M Control Service, SVF Flow Controls, Greggersen, Ningbo Doway M and E Co., Ltd, Zhejiang JUFAN Copper Industry Co., Ltd, AmcareMed |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |