What is Global Light Metal Extrusion Press Market?

The Global Light Metal Extrusion Press Market is a specialized segment within the broader manufacturing industry that focuses on the production of light metal components through the extrusion process. Extrusion is a technique where metal is forced through a die to create objects of a fixed cross-sectional profile. This market primarily deals with metals like aluminum, copper, and other light metals, which are favored for their lightweight and durable properties. These metals are essential in various industries, including automotive, aerospace, construction, and electronics, due to their ability to be shaped into complex forms while maintaining strength and reducing weight. The market is driven by the increasing demand for lightweight materials that contribute to energy efficiency and sustainability. As industries continue to innovate and seek materials that offer both performance and environmental benefits, the Global Light Metal Extrusion Press Market is poised to play a crucial role in meeting these needs. The market's growth is supported by technological advancements in extrusion press machinery, which enhance production efficiency and product quality. Overall, this market is integral to the development of modern infrastructure and technology, providing essential components that support a wide range of applications.

Aluminium Extrusion Press, Copper Extrusion Press, Other in the Global Light Metal Extrusion Press Market:

Aluminum Extrusion Presses are a significant part of the Global Light Metal Extrusion Press Market, known for their versatility and efficiency in producing a wide array of products. Aluminum is a preferred material due to its lightweight, corrosion resistance, and excellent strength-to-weight ratio. These presses are used to create components for industries such as automotive, aerospace, and construction. The process involves heating aluminum billets and forcing them through a die to create shapes like rods, tubes, and profiles. This method allows for the production of complex cross-sections and is highly efficient, making it ideal for mass production. The demand for aluminum extrusion presses is driven by the need for lightweight materials that contribute to fuel efficiency and reduced emissions in vehicles and aircraft. Copper Extrusion Presses, on the other hand, cater to industries that require excellent electrical conductivity and thermal properties. Copper is widely used in electrical applications, plumbing, and telecommunications. The extrusion process for copper involves similar techniques as aluminum but requires different handling due to copper's distinct properties. These presses are crucial for producing components like electrical connectors, bus bars, and heat exchangers. The demand for copper extrusion presses is fueled by the growing need for efficient electrical systems and infrastructure development. Other light metal extrusion presses include those for metals like magnesium and titanium. Magnesium is valued for its ultra-lightweight properties and is used in applications where weight reduction is critical, such as in automotive and aerospace industries. Titanium, known for its strength and corrosion resistance, is used in high-performance applications, including medical devices and aerospace components. The extrusion process for these metals requires specialized equipment and expertise due to their unique characteristics. The Global Light Metal Extrusion Press Market is characterized by continuous innovation and technological advancements. Manufacturers are investing in research and development to improve the efficiency and capabilities of extrusion presses. This includes the development of automated systems, advanced control technologies, and eco-friendly processes that reduce energy consumption and waste. As industries continue to evolve and demand more sophisticated and sustainable materials, the market for light metal extrusion presses is expected to grow. The versatility and adaptability of these presses make them indispensable in modern manufacturing, providing solutions that meet the diverse needs of various industries.

Transportation, Construction, Machinery, Other in the Global Light Metal Extrusion Press Market:

The Global Light Metal Extrusion Press Market finds extensive usage across several key industries, each benefiting from the unique properties of light metals. In the transportation sector, light metal extrusion presses are crucial for producing components that contribute to vehicle weight reduction, leading to improved fuel efficiency and reduced emissions. Aluminum, in particular, is widely used in the automotive and aerospace industries for manufacturing parts such as frames, panels, and structural components. The ability to produce complex shapes with high precision makes extrusion presses ideal for creating lightweight yet strong parts that enhance vehicle performance and safety. In the construction industry, light metal extrusion presses are used to produce a variety of building materials, including window frames, curtain walls, and structural components. The corrosion resistance and durability of metals like aluminum make them suitable for use in harsh environmental conditions, ensuring long-lasting and low-maintenance structures. The versatility of extrusion presses allows for the creation of custom profiles that meet specific architectural and engineering requirements, contributing to innovative building designs and sustainable construction practices. The machinery sector also benefits from the capabilities of light metal extrusion presses. These presses are used to manufacture components for industrial equipment, machinery, and tools. The strength and lightweight properties of extruded metals enhance the performance and efficiency of machinery, reducing operational costs and improving productivity. The ability to produce intricate shapes and designs enables manufacturers to create specialized components that meet the demands of modern industrial applications. Beyond these primary industries, light metal extrusion presses are also used in other areas such as electronics, consumer goods, and renewable energy. In electronics, the excellent thermal and electrical conductivity of metals like copper and aluminum make them ideal for producing heat sinks, connectors, and enclosures. In the renewable energy sector, extruded components are used in solar panel frames, wind turbine parts, and other energy-efficient systems. The adaptability of extrusion presses to produce a wide range of products makes them essential in supporting the development of sustainable technologies and solutions. Overall, the Global Light Metal Extrusion Press Market plays a vital role in various industries by providing the means to produce high-quality, lightweight, and durable components. The ongoing demand for energy-efficient and sustainable materials continues to drive the growth and innovation within this market, ensuring its relevance in the ever-evolving industrial landscape.

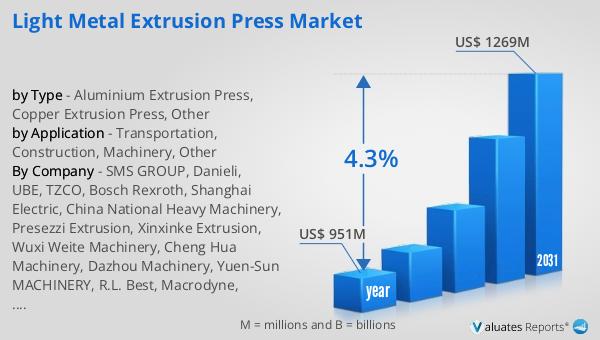

Global Light Metal Extrusion Press Market Outlook:

The global market for Light Metal Extrusion Press was valued at $951 million in 2024, and it is anticipated to expand to a revised size of $1,269 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.3% over the forecast period. This growth trajectory underscores the increasing demand for light metal extrusion presses across various industries, driven by the need for lightweight, durable, and efficient materials. The market's expansion is fueled by advancements in technology and the continuous push for innovation in manufacturing processes. As industries strive to enhance performance while reducing environmental impact, the adoption of light metal extrusion presses becomes increasingly critical. These presses offer the capability to produce complex shapes with precision, catering to the evolving needs of sectors such as automotive, aerospace, construction, and electronics. The projected growth in the market highlights the importance of light metal extrusion presses in supporting the development of sustainable and energy-efficient solutions. As the market continues to evolve, manufacturers are expected to invest in research and development to further enhance the capabilities and efficiency of extrusion presses, ensuring their continued relevance in the global industrial landscape.

| Report Metric | Details |

| Report Name | Light Metal Extrusion Press Market |

| Accounted market size in year | US$ 951 million |

| Forecasted market size in 2031 | US$ 1269 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SMS GROUP, Danieli, UBE, TZCO, Bosch Rexroth, Shanghai Electric, China National Heavy Machinery, Presezzi Extrusion, Xinxinke Extrusion, Wuxi Weite Machinery, Cheng Hua Machinery, Dazhou Machinery, Yuen-Sun MACHINERY, R.L. Best, Macrodyne, EXTRAL Technology, GIA Clecim Press, Wuxi Yimeide |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |