What is Global Helical Submerged Arc Welded Pipe Market?

The Global Helical Submerged Arc Welded (HSAW) Pipe Market is a significant segment within the broader steel pipe industry. These pipes are manufactured using a helical or spiral welding process, which involves forming a continuous strip of steel into a cylindrical shape and then welding the edges together. This method allows for the production of large-diameter pipes, which are essential for various industrial applications. HSAW pipes are known for their strength, durability, and ability to withstand high pressure, making them ideal for transporting oil, gas, and water over long distances. The market for these pipes is driven by the growing demand for energy and infrastructure development worldwide. As countries continue to invest in pipelines for oil and gas transportation, as well as water supply systems, the demand for HSAW pipes is expected to rise. Additionally, advancements in welding technology and materials have improved the quality and efficiency of these pipes, further boosting their market appeal. Overall, the Global Helical Submerged Arc Welded Pipe Market plays a crucial role in supporting the infrastructure and energy needs of modern society.

Roll Forming, Down Roll Forming in the Global Helical Submerged Arc Welded Pipe Market:

Roll forming is a continuous bending operation in which a long strip of sheet metal, usually coiled steel, is passed through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section profile is obtained. This process is highly efficient and is used to produce a wide variety of cross-section profiles, including those used in the manufacturing of Helical Submerged Arc Welded (HSAW) pipes. In the context of the Global HSAW Pipe Market, roll forming is a critical step in shaping the steel strip into the cylindrical form required for pipe production. The precision and consistency offered by roll forming ensure that the pipes meet the stringent specifications needed for industrial applications. Down roll forming, on the other hand, is a variation of the traditional roll forming process. It involves the use of downward pressure to shape the metal strip, which can be particularly useful in producing thicker or more complex profiles. In the HSAW pipe manufacturing process, down roll forming can be employed to achieve specific design requirements or to enhance the structural integrity of the pipes. This technique allows manufacturers to produce pipes that can withstand higher pressures and more demanding environmental conditions. The use of roll forming and down roll forming in the production of HSAW pipes highlights the importance of precision engineering and advanced manufacturing techniques in the steel pipe industry. These processes not only ensure the quality and reliability of the pipes but also contribute to the overall efficiency and cost-effectiveness of the production process. As the demand for HSAW pipes continues to grow, manufacturers are likely to invest in further advancements in roll forming technology to meet the evolving needs of the market. The integration of automation and digital technologies in roll forming processes is also expected to enhance production capabilities and reduce lead times, providing a competitive edge to manufacturers in the Global HSAW Pipe Market. Overall, roll forming and down roll forming are integral to the production of high-quality HSAW pipes, supporting the infrastructure and energy sectors worldwide.

Chemical Industry, Power Industry, Mining Industry, Others in the Global Helical Submerged Arc Welded Pipe Market:

The Global Helical Submerged Arc Welded (HSAW) Pipe Market finds extensive usage across various industries, including the chemical, power, and mining sectors, among others. In the chemical industry, HSAW pipes are utilized for the transportation of raw materials and finished products. Their ability to withstand corrosive substances and high pressures makes them ideal for handling chemicals safely and efficiently. The durability and reliability of these pipes ensure minimal maintenance and downtime, which is crucial for maintaining continuous operations in chemical plants. In the power industry, HSAW pipes play a vital role in the construction of pipelines for transporting natural gas and other fuels to power plants. The high-pressure resistance and structural integrity of these pipes make them suitable for long-distance transportation, ensuring a steady supply of fuel for electricity generation. Additionally, HSAW pipes are used in the construction of cooling water systems and other infrastructure within power plants, contributing to their overall efficiency and performance. The mining industry also relies on HSAW pipes for various applications, including the transportation of slurry, water, and other materials. The robust construction of these pipes allows them to withstand the harsh conditions often encountered in mining operations, such as abrasive materials and extreme temperatures. This durability ensures that the pipes can operate effectively over extended periods, reducing the need for frequent replacements and repairs. Beyond these industries, HSAW pipes are used in a wide range of other applications, including water supply systems, sewage treatment, and infrastructure projects. Their versatility and adaptability make them a preferred choice for many engineering and construction projects worldwide. As the demand for infrastructure development and energy resources continues to grow, the usage of HSAW pipes is expected to expand further, supporting the needs of various industries and contributing to global economic growth.

Global Helical Submerged Arc Welded Pipe Market Outlook:

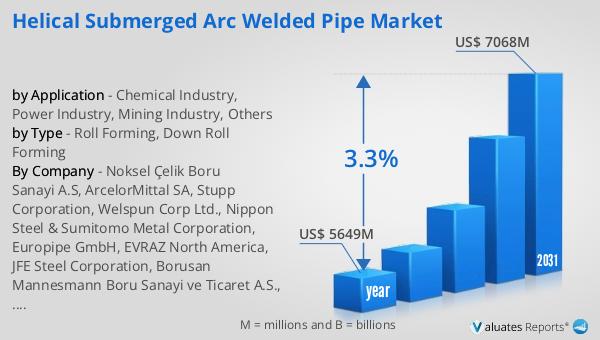

In 2024, the global market for Helical Submerged Arc Welded (HSAW) Pipes was valued at approximately 5,649 million US dollars. Looking ahead, this market is anticipated to grow, reaching an estimated size of 7,068 million US dollars by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.3% over the forecast period. This steady increase in market size reflects the rising demand for HSAW pipes across various industries, driven by the need for robust and reliable infrastructure solutions. The consistent growth rate underscores the importance of these pipes in supporting the energy, construction, and industrial sectors. As countries continue to invest in infrastructure development and energy projects, the demand for high-quality HSAW pipes is expected to remain strong. This market outlook highlights the critical role that HSAW pipes play in meeting the infrastructure and energy needs of modern society, ensuring the efficient and safe transportation of essential resources.

| Report Metric | Details |

| Report Name | Helical Submerged Arc Welded Pipe Market |

| Accounted market size in year | US$ 5649 million |

| Forecasted market size in 2031 | US$ 7068 million |

| CAGR | 3.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Noksel Çelik Boru Sanayi A.S, ArcelorMittal SA, Stupp Corporation, Welspun Corp Ltd., Nippon Steel & Sumitomo Metal Corporation, Europipe GmbH, EVRAZ North America, JFE Steel Corporation, Borusan Mannesmann Boru Sanayi ve Ticaret A.S., PAO TMK Group, Kuwait Pipe Industries and Oil Services Company, Man Industries Ltd., National Pipe Company Ltd., PSL Limited, American Cast Iron Pipe Company, Northwest Pipe Company, Shengli Oil & Gas Pipe Holdings Limited, Liaoyang Steel Tube Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |