What is Global Fused Silica Micropowder Market?

The Global Fused Silica Micropowder Market is a specialized segment within the broader materials industry, focusing on the production and distribution of fused silica micropowder. Fused silica, a form of silicon dioxide, is known for its exceptional thermal stability, low thermal expansion, and high resistance to thermal shock, making it an ideal material for various high-tech applications. The micropowder form of fused silica is particularly valued for its fine particle size, which enhances its performance in precision applications. This market caters to industries such as electronics, semiconductors, and optics, where the demand for high-purity and high-performance materials is critical. The growth of this market is driven by the increasing demand for advanced materials in emerging technologies, as well as the ongoing development of new applications for fused silica micropowder. As industries continue to innovate and seek materials that can withstand extreme conditions while maintaining performance, the Global Fused Silica Micropowder Market is poised to play a crucial role in supporting these advancements. The market's expansion is further supported by technological advancements in manufacturing processes, which enhance the quality and consistency of the micropowder, thereby broadening its application scope.

Angular Fused Silica Powder, Spherical Fused Silica Powder in the Global Fused Silica Micropowder Market:

Angular Fused Silica Powder and Spherical Fused Silica Powder are two distinct forms of fused silica micropowder, each with unique properties and applications within the Global Fused Silica Micropowder Market. Angular Fused Silica Powder is characterized by its irregular, jagged particle shape, which provides a larger surface area compared to its spherical counterpart. This increased surface area enhances the powder's mechanical interlocking capabilities, making it particularly useful in applications where strong adhesion and bonding are required. For instance, in the production of high-performance coatings and adhesives, the angular shape of the particles allows for better mechanical grip, resulting in improved durability and performance of the final product. Additionally, Angular Fused Silica Powder is often used in the manufacturing of precision casting molds, where its shape contributes to the creation of detailed and accurate molds that can withstand high temperatures without deformation. On the other hand, Spherical Fused Silica Powder is known for its smooth, round particle shape, which offers distinct advantages in terms of flowability and packing density. The spherical shape allows the powder to flow more easily, reducing the risk of clogging and ensuring uniform distribution in various applications. This property is particularly beneficial in the production of electronic components, where precise and consistent material distribution is crucial for optimal performance. The high packing density of Spherical Fused Silica Powder also contributes to its use in applications requiring high thermal conductivity and low thermal expansion, such as in the manufacturing of thermal interface materials and encapsulants for electronic devices. Furthermore, the smooth surface of the spherical particles minimizes friction and wear, making it an ideal choice for applications involving high-speed processing or movement. Both Angular and Spherical Fused Silica Powders are integral to the Global Fused Silica Micropowder Market, each serving specific needs and applications across various industries. The choice between angular and spherical forms depends largely on the specific requirements of the application, such as the need for mechanical strength, thermal stability, or ease of processing. As industries continue to evolve and demand more specialized materials, the versatility and adaptability of these two forms of fused silica micropowder ensure their continued relevance and importance in the market. The development of new manufacturing techniques and the exploration of novel applications further enhance the potential of Angular and Spherical Fused Silica Powders, driving innovation and growth within the Global Fused Silica Micropowder Market.

Semiconductors Encapsulants, Hole-plugging Materials, Die Bonding Materials, Others in the Global Fused Silica Micropowder Market:

The Global Fused Silica Micropowder Market finds extensive usage in several critical areas, including Semiconductors Encapsulants, Hole-plugging Materials, Die Bonding Materials, and other specialized applications. In the realm of Semiconductors Encapsulants, fused silica micropowder is prized for its ability to provide excellent thermal stability and electrical insulation. These properties are essential in protecting semiconductor devices from environmental factors such as moisture, dust, and mechanical stress. The micropowder's fine particle size ensures a uniform encapsulation layer, which is crucial for maintaining the performance and longevity of semiconductor components. As the demand for smaller and more efficient electronic devices continues to grow, the role of fused silica micropowder in semiconductor encapsulation becomes increasingly vital. In the production of Hole-plugging Materials, fused silica micropowder is used to fill and seal holes or gaps in electronic components and printed circuit boards (PCBs). The material's high purity and low thermal expansion make it an ideal choice for this application, as it can withstand the thermal cycling and mechanical stresses encountered during the operation of electronic devices. The use of fused silica micropowder in hole-plugging materials helps to enhance the reliability and performance of electronic assemblies, reducing the risk of failure and extending the lifespan of the devices. Die Bonding Materials represent another significant application area for fused silica micropowder. In this context, the micropowder is used as a filler material in die attach adhesives, which are used to bond semiconductor dies to substrates or packages. The thermal conductivity and low thermal expansion of fused silica micropowder contribute to the efficient dissipation of heat generated by the semiconductor device, preventing overheating and ensuring stable operation. Additionally, the micropowder's fine particle size allows for precise control over the adhesive's viscosity and flow characteristics, facilitating the accurate placement and bonding of semiconductor dies. Beyond these specific applications, the Global Fused Silica Micropowder Market also serves a variety of other industries and uses. For example, fused silica micropowder is employed in the production of high-performance optical components, where its optical clarity and low refractive index are highly valued. It is also used in the manufacturing of advanced ceramics and composites, where its thermal and mechanical properties enhance the performance of the final products. As industries continue to push the boundaries of technology and innovation, the versatility and adaptability of fused silica micropowder ensure its continued relevance and importance across a wide range of applications.

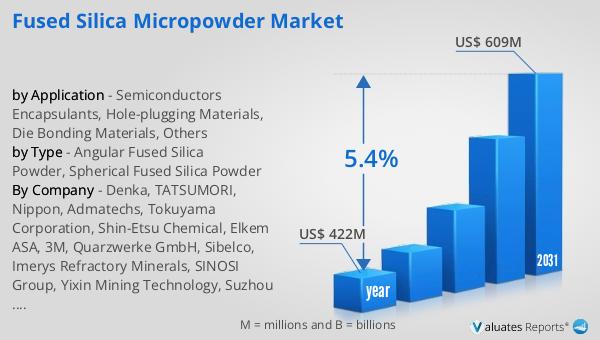

Global Fused Silica Micropowder Market Outlook:

The global market for Fused Silica Micropowder was valued at $422 million in 2024 and is anticipated to grow to a revised size of $609 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.4% over the forecast period. This growth trajectory underscores the increasing demand for high-performance materials across various industries, driven by technological advancements and the need for materials that can withstand extreme conditions. The market's expansion is supported by the ongoing development of new applications for fused silica micropowder, as well as improvements in manufacturing processes that enhance the quality and consistency of the product. As industries continue to innovate and seek materials that offer superior thermal stability, low thermal expansion, and high resistance to thermal shock, the Global Fused Silica Micropowder Market is well-positioned to meet these demands. The projected growth of this market highlights the critical role that fused silica micropowder plays in supporting the advancement of emerging technologies and the development of new products across a wide range of industries.

| Report Metric | Details |

| Report Name | Fused Silica Micropowder Market |

| Accounted market size in year | US$ 422 million |

| Forecasted market size in 2031 | US$ 609 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Denka, TATSUMORI, Nippon, Admatechs, Tokuyama Corporation, Shin-Etsu Chemical, Elkem ASA, 3M, Quarzwerke GmbH, Sibelco, Imerys Refractory Minerals, SINOSI Group, Yixin Mining Technology, Suzhou Ginet New Material, Novoray Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |