What is Global Flexible Nickel Coated Steel Sheets for Battery Case Market?

Global Flexible Nickel Coated Steel Sheets for Battery Case Market refers to a specialized segment within the materials industry that focuses on the production and distribution of nickel-coated steel sheets used in battery casings. These sheets are integral to the manufacturing of various types of batteries, providing essential properties such as corrosion resistance, electrical conductivity, and mechanical strength. The nickel coating on the steel sheets enhances their durability and performance, making them suitable for use in demanding environments where batteries are exposed to various stresses. This market is driven by the increasing demand for batteries in numerous applications, including consumer electronics, electric vehicles, and renewable energy storage systems. As the world shifts towards more sustainable energy solutions, the need for efficient and reliable battery components like nickel-coated steel sheets is expected to grow. Manufacturers in this market are continually innovating to improve the quality and performance of these sheets, ensuring they meet the evolving needs of battery producers and end-users. The global market for these materials is characterized by a mix of established players and new entrants, all competing to provide high-quality products that meet stringent industry standards.

Diffusion Annealed Ni-Top, Gloss Ni-Top, Matte Ni-Top, Semi-Gloss Ni-Top in the Global Flexible Nickel Coated Steel Sheets for Battery Case Market:

Diffusion Annealed Ni-Top, Gloss Ni-Top, Matte Ni-Top, and Semi-Gloss Ni-Top are specific types of nickel coatings applied to steel sheets used in battery cases, each offering unique properties tailored to different applications. Diffusion Annealed Ni-Top involves a heat treatment process that enhances the adhesion and uniformity of the nickel coating on the steel substrate. This process improves the corrosion resistance and mechanical properties of the sheets, making them ideal for use in environments where batteries are subjected to high temperatures and corrosive conditions. The diffusion annealing process ensures that the nickel coating is well-integrated with the steel, providing a robust and durable surface that can withstand the rigors of battery manufacturing and operation. Gloss Ni-Top, on the other hand, is characterized by its shiny, reflective surface, which is achieved through a specialized finishing process. This type of coating is often used in applications where aesthetic appeal is important, such as in consumer electronics where the battery case may be visible. The glossy finish not only enhances the visual appeal of the battery case but also provides a smooth surface that can improve the efficiency of the battery assembly process. Matte Ni-Top offers a non-reflective, textured surface that is preferred in applications where glare reduction is important. This type of coating is often used in industrial and automotive applications where the battery case is not visible, and the focus is on functionality rather than appearance. The matte finish provides excellent grip and handling characteristics, making it easier to assemble and install batteries in tight spaces. Semi-Gloss Ni-Top strikes a balance between the glossy and matte finishes, offering a subtle sheen that is both aesthetically pleasing and functional. This type of coating is versatile and can be used in a wide range of applications, from consumer electronics to industrial equipment. The semi-gloss finish provides a good compromise between the ease of handling offered by matte finishes and the visual appeal of glossy finishes. Each of these nickel coatings is designed to meet specific performance criteria, ensuring that the steel sheets used in battery cases can withstand the demands of their intended applications. Manufacturers of nickel-coated steel sheets must carefully select the appropriate coating type based on the requirements of their customers, taking into consideration factors such as environmental conditions, aesthetic preferences, and manufacturing processes. By offering a range of coating options, manufacturers can cater to the diverse needs of the battery industry, providing high-quality materials that enhance the performance and reliability of batteries across various sectors.

Cylindrical Lithium-ion Battery, Prismatic Type Battery, Alkaline Batteries in the Global Flexible Nickel Coated Steel Sheets for Battery Case Market:

The usage of Global Flexible Nickel Coated Steel Sheets for Battery Case Market in cylindrical lithium-ion batteries, prismatic type batteries, and alkaline batteries highlights the versatility and importance of these materials in modern battery technology. In cylindrical lithium-ion batteries, nickel-coated steel sheets are used to form the outer casing that protects the internal components of the battery. The cylindrical shape is popular in applications such as power tools, laptops, and electric vehicles due to its high energy density and robust design. The nickel coating on the steel sheets provides excellent corrosion resistance, ensuring the longevity and reliability of the battery even in harsh environments. Additionally, the mechanical strength of the steel casing helps protect the battery from physical damage, which is crucial for maintaining safety and performance. In prismatic type batteries, which are commonly used in smartphones, tablets, and electric vehicles, nickel-coated steel sheets are used to create a flat, rectangular casing. This design allows for more efficient use of space, enabling manufacturers to pack more energy into a smaller volume. The nickel coating enhances the thermal and electrical conductivity of the casing, improving the overall efficiency of the battery. The flexibility of the steel sheets also allows for precise shaping and fitting, ensuring a snug fit within the device or vehicle. Alkaline batteries, which are widely used in household electronics such as remote controls, flashlights, and toys, also benefit from the use of nickel-coated steel sheets. The nickel coating provides a protective barrier against leakage and corrosion, which is essential for maintaining the performance and safety of the battery over time. The steel casing offers structural integrity, preventing the battery from deforming or rupturing under pressure. This is particularly important in alkaline batteries, where the chemical reactions can generate significant internal pressure. The use of nickel-coated steel sheets in these various battery types underscores their critical role in ensuring the safety, reliability, and efficiency of modern batteries. As the demand for batteries continues to grow across different sectors, the need for high-quality materials like nickel-coated steel sheets will remain strong. Manufacturers must continue to innovate and improve these materials to meet the evolving needs of the battery industry, ensuring that they can deliver the performance and reliability that consumers and businesses expect.

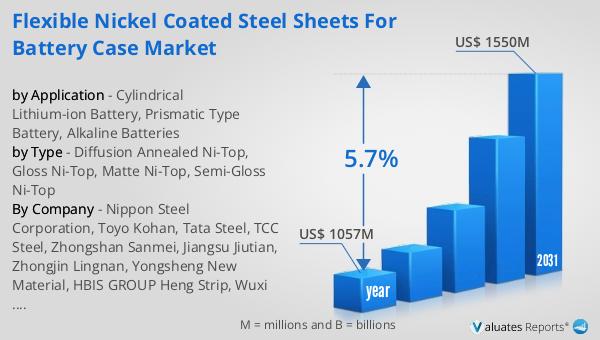

Global Flexible Nickel Coated Steel Sheets for Battery Case Market Outlook:

The global market for Flexible Nickel Coated Steel Sheets for Battery Case was valued at $1,057 million in 2024 and is anticipated to expand to a revised size of $1,550 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.7% over the forecast period. This growth trajectory underscores the increasing demand for nickel-coated steel sheets, driven by the rising adoption of batteries in various applications such as electric vehicles, consumer electronics, and renewable energy storage. The market's expansion is fueled by the need for durable and efficient battery components that can withstand the rigors of modern technology and environmental conditions. As industries continue to innovate and develop new battery technologies, the demand for high-quality materials like nickel-coated steel sheets is expected to rise. This growth also highlights the importance of continuous research and development in the field, as manufacturers strive to enhance the performance and reliability of their products to meet the evolving needs of the market. The projected increase in market size reflects the broader trend towards sustainable energy solutions and the critical role that advanced materials play in enabling these technologies. As the market continues to grow, companies operating in this space will need to focus on innovation and quality to maintain their competitive edge and meet the demands of their customers.

| Report Metric | Details |

| Report Name | Flexible Nickel Coated Steel Sheets for Battery Case Market |

| Accounted market size in year | US$ 1057 million |

| Forecasted market size in 2031 | US$ 1550 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nippon Steel Corporation, Toyo Kohan, Tata Steel, TCC Steel, Zhongshan Sanmei, Jiangsu Jiutian, Zhongjin Lingnan, Yongsheng New Material, HBIS GROUP Heng Strip, Wuxi Jinyang New Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |