What is Global Cotton Spinning Machinery Market?

The Global Cotton Spinning Machinery Market is a vast and dynamic sector that encompasses a wide range of machinery used in the production of cotton yarn. These machines play a crucial role in the textile industry, transforming raw cotton into spun yarn that is used in the manufacture of a variety of textile products. The machinery involved in this process includes ginning machines, which separate the cotton fibers from the seeds, spinning machines, which twist the fibers into yarn, and winding machines, which wind the yarn onto spools or bobbins for further processing. The market for these machines is global in scope, with key players located in various parts of the world. The demand for cotton spinning machinery is driven by factors such as the global demand for cotton yarn, technological advancements in spinning machinery, and the growth of the textile industry in emerging economies. However, the market also faces challenges such as the high cost of machinery and the need for skilled labor to operate the machines. Despite these challenges, the market for cotton spinning machinery is expected to grow in the coming years, driven by the increasing demand for high-quality cotton yarn and the ongoing technological advancements in the field of spinning machinery.

Ring Spinning, Rotor Spinning, Others in the Global Cotton Spinning Machinery Market:

The Global Cotton Spinning Machinery Market is segmented into different types based on the spinning method used, namely Ring Spinning, Rotor Spinning, and Others. Ring Spinning is the most traditional and widely used method of spinning. It involves drawing out the fibers and twisting them into yarn using a ring and a traveler. This method produces high-quality yarn but is relatively slow and labor-intensive. On the other hand, Rotor Spinning, also known as Open-End Spinning, is a more modern method that involves the use of a rotor to twist the fibers into yarn. This method is faster and less labor-intensive than ring spinning, but the yarn produced is of lower quality. The Others category includes various other spinning methods such as Air-Jet Spinning, Friction Spinning, and Self-Twist Spinning. Each of these methods has its own advantages and disadvantages, and the choice of method depends on factors such as the desired quality of the yarn, the cost of the machinery, and the availability of skilled labor.

Combed Yarn, Carded Yarn in the Global Cotton Spinning Machinery Market:

The Global Cotton Spinning Machinery Market also varies based on the type of yarn produced, namely Combed Yarn and Carded Yarn. Combed Yarn is produced by combing the cotton fibers to align them in the same direction and remove any short fibers. This results in a smoother, finer, and stronger yarn that is used in the manufacture of high-quality textiles. However, the combing process is time-consuming and expensive, which makes combed yarn more costly than carded yarn. Carded Yarn, on the other hand, is produced by carding the cotton fibers to disentangle and clean them, but without aligning them in the same direction or removing the short fibers. This results in a coarser, bulkier, and weaker yarn that is used in the manufacture of lower-quality textiles. However, the carding process is faster and cheaper than the combing process, which makes carded yarn more affordable than combed yarn. The choice between combed yarn and carded yarn depends on factors such as the desired quality of the textile product, the cost of the yarn, and the requirements of the textile manufacturing process.

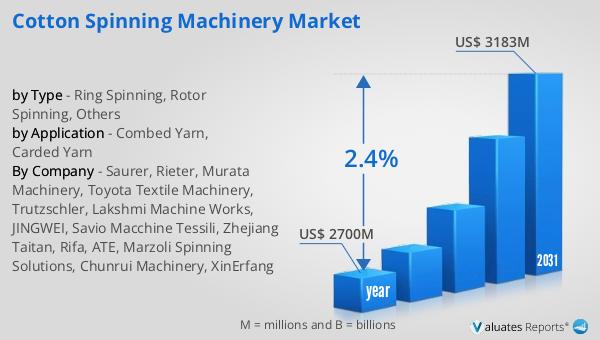

Global Cotton Spinning Machinery Market Outlook:

The Global Cotton Spinning Machinery Market's outlook is promising. In 2022, the market was valued at US$ 2458 million. This figure is expected to rise to US$ 3049 million by 2029, indicating a Compound Annual Growth Rate (CAGR) of 2.4% during the forecast period from 2023 to 2029. This growth is driven by several factors, including the increasing global demand for cotton yarn, the ongoing technological advancements in spinning machinery, and the growth of the textile industry in emerging economies. However, the market also faces challenges such as the high cost of machinery and the need for skilled labor to operate the machines. Despite these challenges, the market for cotton spinning machinery is expected to continue growing in the coming years, driven by the increasing demand for high-quality cotton yarn and the ongoing technological advancements in the field of spinning machinery.

| Report Metric | Details |

| Report Name | Cotton Spinning Machinery Market |

| Accounted market size in 2022 | US$ 2458 in million |

| Forecasted market size in 2029 | US$ 3049 million |

| CAGR | 2.4% |

| Base Year | 2022 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Saurer, Rieter, Murata Machinery, Toyota Textile Machinery, Trutzschler, Lakshmi Machine Works, JINGWEI, Savio Macchine Tessili, Zhejiang Taitan, Rifa, ATE, Marzoli Spinning Solutions, Chunrui Machinery, XinErfang |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |