What is Global Automotive Aluminium Alloy Wheels Market?

The Global Automotive Aluminium Alloy Wheels Market is a vast and dynamic sector that has been gaining significant attention in recent years. This market pertains to the production and distribution of aluminium alloy wheels, which are widely used in the automotive industry. Aluminium alloy wheels are preferred over traditional steel wheels due to their lighter weight, better heat conduction, and more appealing cosmetic appearance. These wheels are made from an alloy of aluminium, which is lighter than other metals used for making wheels such as steel. The lighter weight of the wheels can improve the steering and the speed of the vehicle, making it more fuel-efficient. The global market for these wheels is driven by the increasing demand for lightweight materials in the automotive industry to enhance fuel efficiency and reduce carbon emissions. The market is also influenced by the growing automotive industry worldwide and the increasing demand for passenger and commercial vehicles. However, the market faces challenges such as high production cost and competition from other wheel types. Despite these challenges, the market has immense growth potential due to the increasing focus on vehicle performance and efficiency.

Casting, Forging, Other in the Global Automotive Aluminium Alloy Wheels Market:

The Global Automotive Aluminium Alloy Wheels Market is segmented based on the manufacturing process into Casting, Forging, and Others. Casting is the most common method used for making aluminium alloy wheels. It involves pouring molten aluminium into a mold of the desired wheel shape. The molten aluminium solidifies and cools down to form the wheel. This method is cost-effective and allows for the production of wheels with complex designs. However, cast wheels may have microscopic imperfections that can lead to wheel failure under extreme stress conditions. Forging, on the other hand, involves shaping the wheel under high pressure without melting the aluminium. Forged wheels are stronger and lighter than cast wheels but are more expensive to produce. The Other segment includes methods such as billet machining and hybrid forging. Each of these methods has its advantages and disadvantages, and the choice of method depends on factors such as the desired wheel properties, production cost, and manufacturing capabilities.

Passenger Vehicle, Commercial Vehicle in the Global Automotive Aluminium Alloy Wheels Market:

The Global Automotive Aluminium Alloy Wheels Market finds extensive application in both Passenger Vehicles and Commercial Vehicles. In Passenger Vehicles, aluminium alloy wheels are used to enhance vehicle performance and fuel efficiency. They also add to the aesthetic appeal of the vehicle, making it more attractive to consumers. The demand for aluminium alloy wheels in passenger vehicles is driven by the increasing consumer preference for lightweight and fuel-efficient vehicles. In Commercial Vehicles, aluminium alloy wheels are used to reduce the vehicle's weight and improve its load-carrying capacity. They also improve the vehicle's fuel efficiency, which is a critical factor in the commercial vehicle sector due to the high mileage of these vehicles. The demand for aluminium alloy wheels in commercial vehicles is driven by the increasing need for fuel-efficient and high-performance vehicles in the logistics and transportation industry.

Global Automotive Aluminium Alloy Wheels Market Outlook:

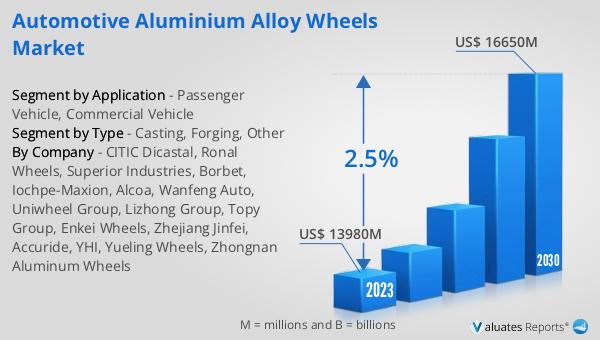

The Global Automotive Aluminium Alloy Wheels Market, which was valued at US$ 13980 million in 2022, is projected to reach a value of US$ 16650 million by 2029. This represents a Compound Annual Growth Rate (CAGR) of 2.5% during the forecast period from 2023 to 2029. The market is dominated by the top four manufacturers, who collectively hold a market share of over 35%. In terms of product types, Casting is the largest segment in the market, accounting for nearly 80% of the total market share. This dominance of the Casting segment can be attributed to its cost-effectiveness and the ability to produce wheels with complex designs. However, other manufacturing methods such as Forging and Others also hold a significant share in the market, indicating a diverse market landscape.

| Report Metric | Details |

| Report Name | Automotive Aluminium Alloy Wheels Market |

| Accounted market size in 2022 | US$ 13980 in million |

| Forecasted market size in 2029 | US$ 16650 million |

| CAGR | 2.5% |

| Base Year | 2022 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CITIC Dicastal, Ronal Wheels, Superior Industries, Borbet, Iochpe-Maxion, Alcoa, Wanfeng Auto, Uniwheel Group, Lizhong Group, Topy Group, Enkei Wheels, Zhejiang Jinfei, Accuride, YHI, Yueling Wheels, Zhongnan Aluminum Wheels |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |