What is Rotary Friction Welding - Global Market?

Rotary Friction Welding is a solid-state welding process that generates heat through mechanical friction between a rotating workpiece and a stationary component. It's a method that has been gaining traction in the global market due to its efficiency and versatility. The process involves the use of a non-consumable tool to generate frictional heat at the interface of the two parts to be joined. This heat, along with a controlled force, leads to the formation of a high-quality, solid-state weld. There are three main types of Rotary Friction Welding: Inertia Rotary Friction Welding, Direct Drive Rotary Friction Welding, and Hybrid Rotary Friction Welding. Inertia Rotary Friction Welding involves the use of a flywheel to store energy which is then transferred to the workpiece to create the necessary heat for welding. Direct Drive Rotary Friction Welding, on the other hand, uses a motor to directly drive the rotational motion. Hybrid Rotary Friction Welding is a combination of the two, utilizing both a flywheel and a motor to generate the frictional heat. Each of these types has its own advantages and is suited to different applications, depending on the specific requirements of the task at hand.

Inertia Rotary Friction Welding, Direct Drive Rotary Friction Welding, Hybrid Rotary Friction Welding in the Rotary Friction Welding - Global Market:

Rotary Friction Welding has a wide range of applications in various industries. In the automotive manufacturing industry, it is used for the production of parts such as axles, drive shafts, and steering columns. The process offers a high degree of precision and reliability, making it ideal for the production of critical components. In the cutting tool manufacturing industry, Rotary Friction Welding is used to join different materials, allowing for the creation of tools with optimal properties. In the aviation and shipbuilding industries, the process is used to produce large, complex components. It is also used in the manufacturing of machine components, hydraulic/pneumatic parts, and electric and wiring parts. Other applications include the production of medical devices, construction equipment, and various consumer products.

Automotive Manufacturing, Cutting Tool Manufacturing, Aviation & Shipbuilding, Machine Components, Hydraulic/Pneumatic Parts, Electric and Wiring Parts, Others in the Rotary Friction Welding - Global Market:

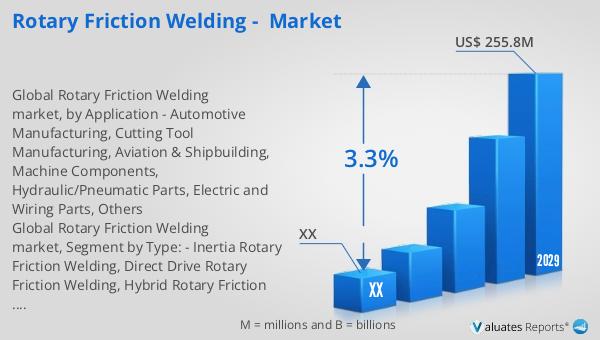

The global market outlook for Rotary Friction Welding is positive. In 2022, the welding market was valued at US$ 203 million. It is projected to grow to US$ 255.8 million by 2029, representing a compound annual growth rate (CAGR) of 3.3% during the forecast period from 2023 to 2029. This growth is driven by the increasing demand for efficient and reliable welding solutions in various industries. The market is dominated by the top four manufacturers, who collectively hold a market share of about 65%. This indicates a high level of concentration in the market, with a few key players exerting significant influence.

Rotary Friction Welding - Global Market Outlook:

In conclusion, Rotary Friction Welding is a versatile and efficient welding process that is gaining increasing recognition in the global market. Its wide range of applications in various industries, coupled with the positive market outlook, suggests that it will continue to play a significant role in the welding industry in the years to come.

| Report Metric | Details |

| Report Name | Rotary Friction Welding - Market |

| Forecasted market size in 2029 | US$ 255.8 million |

| CAGR | 3.3% |

| Forecasted years | 2023 - 2029 |

| Global Rotary Friction Welding market, by region: |

|

| Global Rotary Friction Welding market, Segment by Type: |

|

| Global Rotary Friction Welding market, by Application |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |