What is Global On-Site Milling Market?

The Global On-Site Milling Market is a fascinating and complex sector of the industrial world. It refers to the practice of using specialized equipment to perform milling operations on-site, rather than in a traditional factory setting. This can include a wide range of activities, from the milling of large-scale industrial components to the precision machining of smaller parts. The key advantage of on-site milling is that it allows for greater flexibility and efficiency, as it eliminates the need for transporting heavy and bulky items to and from a factory. This can result in significant cost and time savings, making it an attractive option for many businesses. However, it's important to note that on-site milling requires a high level of expertise and specialized equipment, which can be a barrier to entry for some companies.

Linear and Gantry Milling, Orbital Milling in the Global On-Site Milling Market:

Linear and Gantry Milling, as well as Orbital Milling, are key components of the Global On-Site Milling Market. Linear milling machines are designed to machine flat and level surfaces, while gantry milling machines are used for machining large components, such as castings and weldments. Orbital milling, on the other hand, involves the use of a rotating cutting tool that moves in a circular path around the workpiece. This can be particularly useful for machining large circular components, such as flanges or large diameter pipes. Each of these types of milling has its own unique advantages and applications, and the choice between them will depend on the specific requirements of the job at hand.

Oil & Gas, Power Industry, Marine, General Industry in the Global On-Site Milling Market:

The Global On-Site Milling Market finds its usage in a variety of sectors including Oil & Gas, Power Industry, Marine, and General Industry. In the Oil & Gas sector, on-site milling is used for tasks such as drilling, boring, and reaming, which are critical for the extraction and refining processes. In the Power Industry, it is used for the maintenance and repair of large-scale equipment such as turbines and generators. The Marine industry uses on-site milling for the repair and maintenance of ship components, while the General Industry uses it for a wide range of applications, from the production of large-scale machinery to the precision machining of small parts.

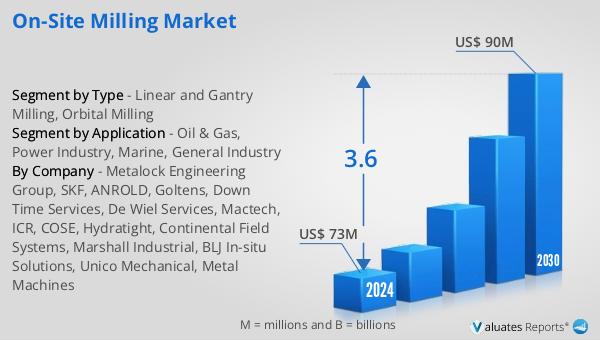

Global On-Site Milling Market Outlook:

The future of the Global On-Site Milling Market looks promising, with a steady growth trajectory predicted for the coming years. In 2022, the market was valued at US$ 73 million, and it is expected to grow to US$ 90 million by 2029. This represents a Compound Annual Growth Rate (CAGR) of 3.6% during the forecast period of 2023-2029. The Asia-Pacific region is a major player in this market, accounting for 40.92% of the total sales in 2019. This dominance can be attributed to the region's robust industrial sector and the increasing adoption of on-site milling in industries such as manufacturing, construction, and energy.

| Report Metric | Details |

| Report Name | On-Site Milling Market |

| Accounted market size in 2022 | US$ 73 in million |

| Forecasted market size in 2029 | US$ 90 million |

| CAGR | 3.6% |

| Base Year | 2022 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Metalock Engineering Group, SKF, ANROLD, Goltens, Down Time Services, De Wiel Services, Mactech, ICR, COSE, Hydratight, Continental Field Systems, Marshall Industrial, BLJ In-situ Solutions, Unico Mechanical, Metal Machines |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |