What is Global High Temperature Coatings for Aerospace Market?

The Global High Temperature Coatings for Aerospace Market is a fascinating and complex field that is rapidly evolving. These coatings are specifically designed to withstand extreme temperatures, often in excess of 600 degrees Celsius, which are commonly encountered in aerospace applications. They are used to protect various components of aircraft, spacecraft, and other aerospace equipment from the damaging effects of high temperatures, such as oxidation, corrosion, and thermal fatigue. These coatings are typically made from a variety of materials, including ceramics, metals, and organic compounds, each with its own unique set of properties and advantages.

Ceramic-based Coatings, Metallic-based Coatings, Organic-based Coatings, Other in the Global High Temperature Coatings for Aerospace Market:

Ceramic-based coatings are one of the most popular types of high temperature coatings used in the aerospace industry. These coatings are known for their excellent thermal resistance, high hardness, and low thermal conductivity, making them ideal for protecting components that are exposed to extreme heat. Metallic-based coatings, on the other hand, are often used for their superior corrosion resistance and thermal conductivity. These coatings are typically made from metals such as aluminum, zinc, and nickel, and are often used to protect components that are exposed to corrosive environments. Organic-based coatings are another type of high temperature coating that is commonly used in the aerospace industry. These coatings are typically made from organic compounds such as polyimides, polyamides, and polyesters, and are known for their excellent chemical resistance, flexibility, and adhesion properties. Other types of high temperature coatings used in the aerospace industry include those made from materials such as silicones, epoxies, and polyurethanes. These coatings are often used for their unique combination of properties, including high thermal resistance, excellent adhesion, and good chemical resistance.

Interior, Exterior, Other in the Global High Temperature Coatings for Aerospace Market:

High temperature coatings are used in a variety of applications in the aerospace industry. One of the most common applications is in the interior of aircraft and spacecraft, where they are used to protect components such as engines, turbines, and exhaust systems from the damaging effects of high temperatures. These coatings are also used on the exterior of aerospace equipment, where they provide protection against the harsh environmental conditions encountered during flight, such as extreme temperatures, UV radiation, and corrosive atmospheres. Other applications of high temperature coatings in the aerospace industry include their use on components such as landing gear, hydraulic systems, and electrical systems, where they provide protection against corrosion, wear, and other forms of damage.

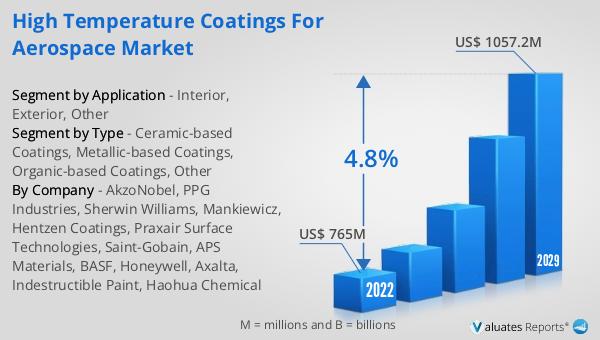

Global High Temperature Coatings for Aerospace Market Outlook:

According to a recent survey, the global High Temperature Coatings for Aerospace market is expected to experience significant growth over the next few years. The market, which was valued at US$ 765 million in 2022, is projected to reach a value of US$ 1057.2 million by 2029. This represents a compound annual growth rate (CAGR) of 4.8% during the period from 2023 to 2029. This growth is expected to be driven by a number of factors, including the increasing demand for high temperature coatings in the aerospace industry, the ongoing technological advancements in the field of high temperature coatings, and the growing awareness of the benefits of these coatings in terms of improving the performance and lifespan of aerospace equipment.

| Report Metric | Details |

| Report Name | High Temperature Coatings for Aerospace Market |

| Accounted market size in 2022 | US$ 765 million |

| Forecasted market size in 2029 | US$ 1057.2 million |

| CAGR | 4.8% |

| Base Year | 2022 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AkzoNobel, PPG Industries, Sherwin Williams, Mankiewicz, Hentzen Coatings, Praxair Surface Technologies, Saint-Gobain, APS Materials, BASF, Honeywell, Axalta, Indestructible Paint, Haohua Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |