What is Global Anti-Corrosion Coatings for Petrifaction Market?

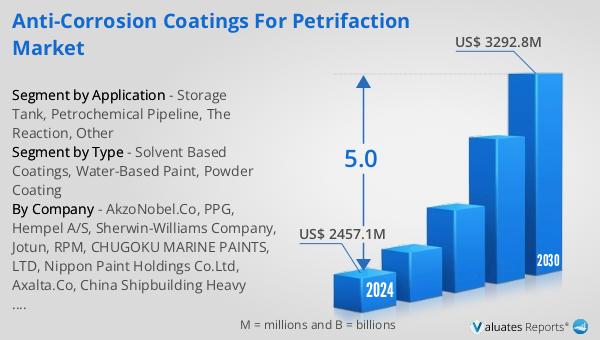

The Global Anti-Corrosion Coatings for Petrifaction Market is a specialized sector that focuses on the production and application of protective coatings designed to prevent corrosion in petrochemical industries. These coatings are essential in maintaining the integrity and longevity of equipment and infrastructure used in petrochemical processes. The market is driven by the need to protect valuable assets from the damaging effects of corrosion, which can lead to costly repairs, downtime, and even catastrophic failures. The global market was valued at US$ 2330.7 million in 2022 and is projected to reach US$ 3292.8 million by 2029, growing at a compound annual growth rate (CAGR) of 5.0% from 2023 to 2029.

Solvent Based Coatings, Water-Based Paint, Powder Coating in the Global Anti-Corrosion Coatings for Petrifaction Market:

The market is segmented into different types of coatings, including Solvent Based Coatings, Water-Based Paint, and Powder Coating. Solvent Based Coatings are typically used in applications where high resistance to chemicals and extreme environmental conditions is required. Water-Based Paint is a more environmentally friendly option, offering good corrosion resistance with less harmful emissions. Powder Coating is a dry finishing process that provides a high-quality, durable finish. The choice of coating depends on the specific requirements of the application, including the type of substrate, the environment in which it will be used, and the desired lifespan of the coating.

Storage Tank, Petrochemical Pipeline, The Reaction, Other in the Global Anti-Corrosion Coatings for Petrifaction Market:

The Anti-Corrosion Coatings for Petrifaction are used in various areas within the petrochemical industry, including Storage Tanks, Petrochemical Pipelines, and Reaction Vessels. Storage Tanks are often exposed to harsh conditions, both internally from the stored substances and externally from the environment, making them susceptible to corrosion. Petrochemical Pipelines transport various chemicals and gases, which can cause corrosion from the inside. Reaction Vessels are used in chemical reactions, where the substances involved can be corrosive. The use of anti-corrosion coatings in these areas helps to prolong the life of the equipment, reduce maintenance costs, and prevent potential safety hazards.

Global Anti-Corrosion Coatings for Petrifaction Market Outlook:

In terms of market outlook, the global Anti-Corrosion Coatings for Petrifaction market is showing promising growth. In 2022, the market was valued at US$ 2330.7 million and is expected to reach US$ 3292.8 million by 2029, growing at a CAGR of 5.0% during the forecast period from 2023 to 2029. North America is the second largest producer of these coatings, accounting for 21.39% of global production in 2019. The market is dominated by major manufacturers such as Akzo Nobel, PPG, Shanghai Old Man, Sherwin-Williams, Jotun, RPM, Tu, Nippon Paint, and YiShi. These top five manufacturers accounted for about 51.37% of the market's output value in 2019.

| Report Metric | Details |

| Report Name | Anti-Corrosion Coatings for Petrifaction Market |

| Accounted market size in 2022 | US$ 2330.7 in million |

| Forecasted market size in 2029 | US$ 3292.8 million |

| CAGR | 5.0% |

| Base Year | 2022 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AkzoNobel.Co, PPG, Hempel A/S, Sherwin-Williams Company, Jotun, RPM, CHUGOKU MARINE PAINTS, LTD, Nippon Paint Holdings Co.Ltd, Axalta.Co, China Shipbuilding Heavy Industry Shuangrui Technology Holding Co., Ltd., Kansai Paint Co.,Ltd., Xiangjiang Paint Group, Zhejiang Yutong New Materials Co., Ltd., Zhejiang Bridge Painting Co. LTD, YUNG CHI PAINT & VARNISH MFG. CO.,LTD, Jiangsu Changjiang Paint Company Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |