What is Global Electrician Safety Belt Market?

The Global Electrician Safety Belt Market is a specialized segment within the broader safety equipment industry, focusing on the production and distribution of safety belts specifically designed for electricians. These belts are crucial for ensuring the safety of electricians who often work at heights or in precarious positions. The market encompasses a variety of products that cater to different needs, including belts made from various materials such as nylon, plastic, and other composites. These belts are designed to provide support and security, reducing the risk of falls and injuries. The market is driven by the increasing emphasis on workplace safety regulations and the growing awareness of the importance of personal protective equipment (PPE) in preventing workplace accidents. As industries continue to prioritize safety, the demand for high-quality electrician safety belts is expected to grow. This market is characterized by continuous innovation, with manufacturers focusing on enhancing the durability, comfort, and functionality of their products to meet the evolving needs of electricians worldwide. The market's growth is also supported by advancements in material technology, which allow for the development of more robust and lightweight safety belts.

Nylon, Plastic, Others in the Global Electrician Safety Belt Market:

In the Global Electrician Safety Belt Market, materials play a crucial role in determining the effectiveness and appeal of the products. Nylon is one of the most commonly used materials due to its strength, durability, and flexibility. Nylon belts are favored for their ability to withstand significant wear and tear, making them ideal for electricians who require reliable support during their work. The material's lightweight nature also ensures that the belts do not add unnecessary weight, allowing electricians to move freely and comfortably. Additionally, nylon's resistance to various environmental factors, such as moisture and UV rays, enhances its longevity, making it a cost-effective choice for both manufacturers and users. On the other hand, plastic is another material used in the production of electrician safety belts. Plastic components are often incorporated into the design to provide additional support and structure. These components can include buckles, clips, and other fastening mechanisms that ensure the belt remains securely in place during use. The use of plastic allows for the creation of adjustable and customizable belts, catering to the diverse needs of electricians. Moreover, plastic's versatility enables manufacturers to experiment with different designs and features, further enhancing the functionality of the belts. Besides nylon and plastic, other materials are also utilized in the market to cater to specific requirements. These can include leather, polyester, and various composite materials that offer unique benefits. Leather, for instance, is known for its classic appearance and durability, making it a popular choice for those who prefer a traditional look. Polyester, on the other hand, offers excellent resistance to chemicals and abrasion, making it suitable for electricians working in harsh environments. Composite materials, which combine the strengths of different substances, are increasingly being used to create innovative safety belts that offer enhanced performance. These materials allow for the development of belts that are not only strong and durable but also lightweight and comfortable. The choice of material is often influenced by factors such as cost, intended use, and personal preference. Manufacturers in the Global Electrician Safety Belt Market continuously explore new materials and technologies to improve their products and meet the evolving demands of their customers. As a result, the market is characterized by a wide range of options, ensuring that electricians can find a safety belt that suits their specific needs and preferences. The ongoing advancements in material science and technology are expected to further drive innovation in the market, leading to the development of even more effective and user-friendly safety belts.

Commercial, Industrial in the Global Electrician Safety Belt Market:

The usage of electrician safety belts in commercial and industrial settings is integral to ensuring the safety and efficiency of electrical work. In commercial environments, such as office buildings, shopping centers, and other public spaces, electricians often need to perform maintenance and installation tasks at various heights. Safety belts provide the necessary support and security, allowing electricians to focus on their work without the constant fear of falling. The belts are designed to distribute weight evenly, reducing strain on the body and minimizing the risk of injury. This is particularly important in commercial settings where electricians may need to navigate complex structures and tight spaces. The use of safety belts in these environments not only protects the workers but also enhances productivity by allowing them to work more confidently and efficiently. In industrial settings, the importance of electrician safety belts is even more pronounced. Industrial environments, such as factories, power plants, and construction sites, often present a higher risk of accidents due to the presence of heavy machinery, hazardous materials, and challenging working conditions. Electricians working in these settings require robust safety equipment to protect them from potential hazards. Safety belts are an essential component of their personal protective equipment, providing the necessary support and stability to perform their tasks safely. The belts are designed to withstand the rigors of industrial work, offering durability and reliability in demanding conditions. Moreover, the use of safety belts in industrial environments is often mandated by safety regulations and standards, emphasizing their importance in maintaining workplace safety. The implementation of safety belts in both commercial and industrial settings is supported by a growing awareness of the importance of workplace safety and the need to comply with safety regulations. Employers are increasingly recognizing the value of investing in high-quality safety equipment to protect their workers and reduce the risk of accidents. This has led to a rise in demand for electrician safety belts that offer superior performance and comfort. Manufacturers are responding to this demand by developing innovative products that cater to the specific needs of commercial and industrial users. These products often feature advanced materials and designs that enhance their functionality and user experience. As a result, the Global Electrician Safety Belt Market continues to evolve, offering a wide range of options for electricians working in various settings. The ongoing focus on safety and innovation is expected to drive further growth in the market, ensuring that electricians have access to the best possible equipment to perform their work safely and effectively.

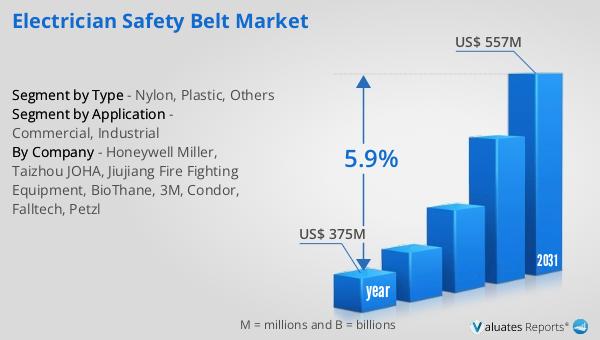

Global Electrician Safety Belt Market Outlook:

The global market for Electrician Safety Belts was valued at $375 million in 2024 and is anticipated to expand to a revised size of $557 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.9% over the forecast period. This growth trajectory underscores the increasing demand for safety equipment in the electrical industry, driven by heightened awareness of workplace safety and stringent regulatory requirements. As industries across the globe continue to prioritize the safety of their workforce, the need for reliable and effective safety belts is becoming more pronounced. The projected growth in the market is indicative of the broader trend towards enhanced safety measures and the adoption of advanced safety technologies. Manufacturers are likely to focus on innovation and product development to meet the evolving needs of electricians, offering belts that provide superior comfort, durability, and functionality. The market's expansion is also supported by the growing construction and industrial sectors, which require robust safety solutions to protect workers in high-risk environments. As the market continues to grow, stakeholders are expected to invest in research and development to create cutting-edge products that align with the latest safety standards and regulations. This focus on innovation and compliance is essential for maintaining a competitive edge in the dynamic and rapidly evolving Global Electrician Safety Belt Market.

| Report Metric | Details |

| Report Name | Electrician Safety Belt Market |

| Accounted market size in year | US$ 375 million |

| Forecasted market size in 2031 | US$ 557 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Honeywell Miller, Taizhou JOHA, Jiujiang Fire Fighting Equipment, BioThane, 3M, Condor, Falltech, Petzl |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |