What is Global Friction Welding Equipment Market?

The Global Friction Welding Equipment Market is a vast and complex field that encompasses a variety of welding techniques and equipment used across numerous industries worldwide. This market is primarily concerned with the production and distribution of friction welding equipment, which utilizes the heat generated from mechanical friction to join or fuse different materials together. The process involves the use of a non-consumable tool to generate frictional heat and plastic deformation at the faying surfaces. This results in a solid-state weld, which is typically stronger and more durable than traditional fusion welds. The global market for this equipment is driven by a variety of factors, including the increasing demand for high-quality welds, the growing need for efficient and cost-effective welding solutions, and the ongoing advancements in friction welding technology. However, the market also faces several challenges, such as the high initial cost of equipment and the need for skilled operators. Despite these challenges, the Global Friction Welding Equipment Market continues to grow and evolve, offering new opportunities and challenges for manufacturers, distributors, and end-users alike.

Rotary Friction Welding, Linear Friction Welding, Friction Stir Welding in the Global Friction Welding Equipment Market:

The Global Friction Welding Equipment Market is segmented based on the type of friction welding technique, which includes Rotary Friction Welding, Linear Friction Welding, and Friction Stir Welding. Rotary Friction Welding involves the rotation of one workpiece against another to generate heat and create a weld. This technique is commonly used for joining round or cylindrical parts, such as pipes and rods. Linear Friction Welding, on the other hand, involves the linear motion of one workpiece against another. This technique is often used for joining flat or rectangular parts, such as plates and sheets. Lastly, Friction Stir Welding involves the use of a rotating tool to stir the materials together and create a weld. This technique is particularly useful for joining materials that are difficult to weld using traditional methods, such as aluminum and other non-ferrous metals. Each of these techniques has its own unique advantages and applications, making them valuable additions to the Global Friction Welding Equipment Market.

Automotive Manufacturing, Tool & Machine Manufacturing, Aviation & Shipbuilding in the Global Friction Welding Equipment Market:

The Global Friction Welding Equipment Market finds extensive usage in several areas including Automotive Manufacturing, Tool & Machine Manufacturing, and Aviation & Shipbuilding. In the automotive manufacturing industry, friction welding equipment is used to join various components of a vehicle, such as the engine, transmission, and chassis. This equipment provides a strong and durable weld that can withstand the harsh conditions and high stresses encountered in automotive applications. In the tool and machine manufacturing industry, friction welding equipment is used to join different parts of a tool or machine, such as the handle and blade of a knife or the shaft and head of a drill. This equipment provides a precise and reliable weld that can ensure the proper functioning and longevity of the tool or machine. In the aviation and shipbuilding industry, friction welding equipment is used to join various parts of an aircraft or ship, such as the fuselage, wings, and hull. This equipment provides a high-quality weld that can withstand the extreme conditions and high pressures encountered in aviation and shipbuilding applications.

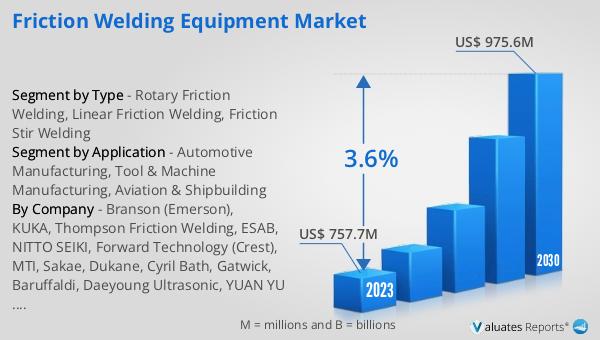

Global Friction Welding Equipment Market Outlook:

Looking at the market outlook, the Global Friction Welding Equipment Market was valued at a significant US$ 757.7 million in 2022. This value is not static, however, as it is projected to reach an impressive US$ 975.6 million by 2029. This indicates a steady growth pattern, with a Compound Annual Growth Rate (CAGR) of 3.6% expected during the forecast period from 2023 to 2029. This growth can be attributed to several factors, including the increasing demand for friction welding equipment in various industries, the ongoing advancements in friction welding technology, and the growing need for efficient and cost-effective welding solutions. However, it's important to note that these projections are based on current market trends and conditions, and actual market performance may vary due to a variety of factors.

| Report Metric | Details |

| Report Name | Friction Welding Equipment Market |

| Accounted market size in 2023 | US$ 789.1 million |

| Forecasted market size in 2029 | US$ 975.6 million |

| CAGR | 3.6 |

| Base Year | 2023 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Branson (Emerson), KUKA, Thompson Friction Welding, ESAB, NITTO SEIKI, Forward Technology (Crest), MTI, Sakae, Dukane, Cyril Bath, Gatwick, Baruffaldi, Daeyoung Ultrasonic, YUAN YU Industrial, Zhengchen, Changchun CNC Machine Tool, Longfei Welding Equipment, HWI, Yuyao City Biweekly, New Dimension Research, Bielomatik, Hornwell |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |