What is Global Friction Stir Welding (FSW) Machines Market?

The Global Friction Stir Welding (FSW) Machines Market is a vast and dynamic field that encompasses a wide range of technologies and applications. At its core, it involves the use of friction stir welding machines, which are specialized devices that use frictional heat combined with a precisely controlled forging pressure to produce high-quality, high-strength welds in a variety of materials. These machines have been adopted across a wide range of industries due to their ability to produce superior welds compared to traditional welding methods. The global market for these machines is substantial and continues to grow as more industries recognize the benefits of this technology.

Conventional, CNC in the Global Friction Stir Welding (FSW) Machines Market:

The Global Friction Stir Welding (FSW) Machines Market can be divided into two main categories: conventional and CNC-based. Conventional FSW machines are typically manually operated and require a high level of skill and experience to use effectively. On the other hand, CNC-based FSW machines are automated and controlled by a computer, which allows for more precise and consistent welds. Both types of machines have their own advantages and disadvantages, and the choice between them often depends on the specific requirements of the application. Despite these differences, both types of machines play a crucial role in the global market and contribute significantly to its overall growth.

Automotive, Railways, Shipbuilding, Aerospace, Others in the Global Friction Stir Welding (FSW) Machines Market:

The Global Friction Stir Welding (FSW) Machines Market finds extensive application in several areas including automotive, railways, shipbuilding, aerospace, among others. In the automotive industry, these machines are used to weld parts of vehicles such as body panels, chassis, and engine components. In the railway industry, they are used to weld parts of trains, including the body and the undercarriage. In shipbuilding, FSW machines are used to weld parts of ships, including the hull and the superstructure. In the aerospace industry, these machines are used to weld parts of aircraft, including the fuselage and the wings. The versatility and effectiveness of FSW machines make them an invaluable tool in these and many other industries.

Global Friction Stir Welding (FSW) Machines Market Outlook:

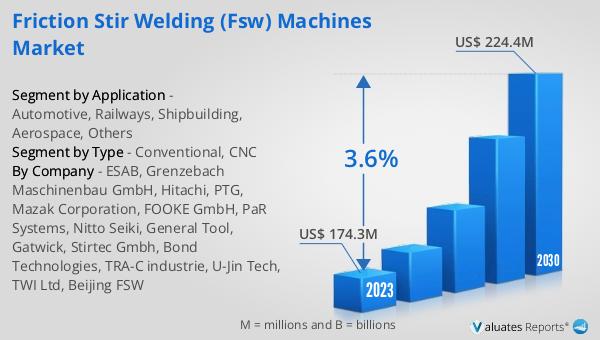

Looking at the market outlook for the Global Friction Stir Welding (FSW) Machines Market, it's clear that this is a sector on the rise. In 2022, the market was valued at a substantial US$ 174.3 million. However, this is just the beginning. It's projected that by 2029, the market will have grown to reach an impressive US$ 224.4 million. This represents a compound annual growth rate (CAGR) of 3.6% during the forecast period from 2023 to 2029. This steady growth is a testament to the increasing recognition of the benefits of friction stir welding technology across a range of industries.

| Report Metric | Details |

| Report Name | Friction Stir Welding (FSW) Machines Market |

| Accounted market size in 2022 | US$ 174.3 million |

| Forecasted market size in 2029 | US$ 224.4 million |

| CAGR | 3.6% |

| Base Year | 2022 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ESAB, Grenzebach Maschinenbau GmbH, Hitachi, PTG, Mazak Corporation, FOOKE GmbH, PaR Systems, Nitto Seiki, General Tool, Gatwick, Stirtec Gmbh, Bond Technologies, TRA-C industrie, U-Jin Tech, TWI Ltd, Beijing FSW |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |