What is Global Non-Destructive Pipe Flaw Detection Equipment Market?

The Global Non-Destructive Pipe Flaw Detection Equipment Market is a specialized sector that focuses on the detection of flaws or defects in pipes without causing any damage to the pipe itself. This technology is crucial in industries where the integrity of pipes is paramount, such as oil and gas, aerospace, and metallurgy. The equipment used in this market is designed to detect any imperfections that could potentially lead to catastrophic failures if left unchecked. These flaws could include cracks, leaks, corrosion, and other forms of damage that could compromise the pipe's structural integrity. The market is driven by the need for safety and efficiency in industries that rely heavily on piping systems. The detection equipment used in this market is often high-tech and utilizes advanced technologies such as ultrasonic testing, radiographic testing, and magnetic particle testing. These technologies allow for accurate and reliable detection of flaws, ensuring the safety and efficiency of the piping systems in use.

Fixed, Portable in the Global Non-Destructive Pipe Flaw Detection Equipment Market:

The Global Non-Destructive Pipe Flaw Detection Equipment Market is segmented into fixed and portable based on the type of equipment. Fixed equipment is typically used in industrial settings where large-scale piping systems are in place. These systems require regular monitoring and maintenance to ensure their continued operation. Fixed detection equipment is often more robust and capable of handling larger volumes of pipes. On the other hand, portable equipment is designed for use in smaller, more localized settings. These devices are often used in field operations where mobility and flexibility are key. They are typically smaller and more lightweight, allowing for easy transportation and use in various locations. Both types of equipment play a crucial role in the market, catering to different needs and applications.

Metallurgy, Aerospace, Oil and Gas, Others in the Global Non-Destructive Pipe Flaw Detection Equipment Market:

The Global Non-Destructive Pipe Flaw Detection Equipment Market finds its application in various sectors such as metallurgy, aerospace, oil and gas, among others. In the metallurgy sector, the equipment is used to detect flaws in the pipes used for transporting molten metal and other materials. In the aerospace industry, the equipment is used to ensure the integrity of the pipes used in aircraft and spacecraft. These pipes are often subjected to extreme conditions and high pressures, making the detection of flaws crucial for safety. In the oil and gas industry, the equipment is used to detect flaws in the pipes used for transporting oil and gas. These pipes are often located in harsh environments and are subjected to corrosive substances, making the detection of flaws crucial for preventing leaks and spills.

Global Non-Destructive Pipe Flaw Detection Equipment Market Outlook:

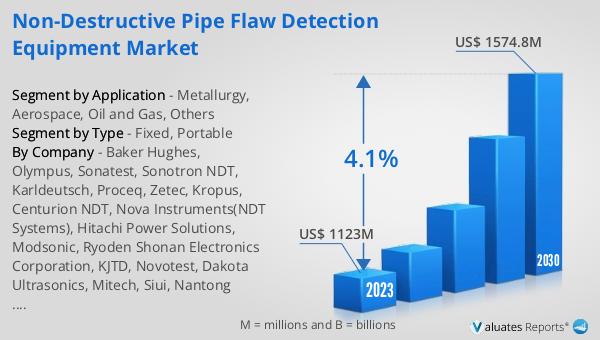

Looking at the market outlook for the Global Non-Destructive Pipe Flaw Detection Equipment Market, it's clear that the sector is on a growth trajectory. In 2022, the market was valued at a significant US$ 1123 million. This figure is expected to rise to an impressive US$ 1574.8 million by 2029. This represents a Compound Annual Growth Rate (CAGR) of 4.1% during the forecast period from 2023 to 2029. This growth is driven by the increasing demand for safety and efficiency in industries that rely heavily on piping systems. The need for reliable and accurate detection of flaws in these systems is paramount, and this is where the Non-Destructive Pipe Flaw Detection Equipment comes into play. The market's growth is a testament to the importance of this technology in ensuring the safety and efficiency of piping systems across various industries.

| Report Metric | Details |

| Report Name | Non-Destructive Pipe Flaw Detection Equipment Market |

| Accounted market size in 2022 | US$ 1123 in million |

| Forecasted market size in 2029 | US$ 1574.8 million |

| CAGR | 4.1% |

| Base Year | 2022 |

| Forecasted years | 2023 - 2029 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Baker Hughes, Olympus, Sonatest, Sonotron NDT, Karldeutsch, Proceq, Zetec, Kropus, Centurion NDT, Nova Instruments(NDT Systems), Hitachi Power Solutions, Modsonic, Ryoden Shonan Electronics Corporation, KJTD, Novotest, Dakota Ultrasonics, Mitech, Siui, Nantong YouLian, Doppler, Wuhan Zhongke Innovation, RDM |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |