What is Global Automatic Gel Documentation System Market?

The Global Automatic Gel Documentation System Market is a specialized segment within the broader life sciences and biotechnology industry. This market focuses on systems designed to automate the process of documenting and analyzing gel electrophoresis results. Gel electrophoresis is a laboratory technique used to separate mixtures of DNA, RNA, or proteins based on their size and charge. The automatic gel documentation systems are equipped with advanced imaging technologies, software, and hardware that allow researchers to capture high-resolution images of gels, analyze the data, and store the results efficiently. These systems are crucial for ensuring accuracy, reproducibility, and efficiency in molecular biology experiments. They are widely used in research institutions, pharmaceutical companies, and diagnostic laboratories. The market has seen significant growth due to the increasing demand for high-throughput and automated solutions in life sciences research. Technological advancements, such as the integration of artificial intelligence and machine learning for enhanced data analysis, have further propelled the market. Additionally, the growing focus on personalized medicine and genomics research has increased the need for precise and reliable gel documentation systems. Overall, the Global Automatic Gel Documentation System Market plays a vital role in advancing scientific research and improving the accuracy of molecular diagnostics.

Colorimetric, Fluorescence in the Global Automatic Gel Documentation System Market:

Colorimetric and fluorescence-based methods are two primary techniques used in the Global Automatic Gel Documentation System Market. Colorimetric methods involve the use of dyes or stains that bind to specific molecules, such as DNA, RNA, or proteins, and produce a color change that can be detected and quantified. These methods are relatively simple and cost-effective, making them popular for routine laboratory use. Common colorimetric stains include Coomassie Blue for proteins and ethidium bromide for nucleic acids. The colorimetric technique is advantageous because it does not require sophisticated equipment and can be easily visualized with the naked eye or basic imaging systems. However, it may lack the sensitivity and specificity needed for certain applications. On the other hand, fluorescence-based methods involve the use of fluorescent dyes or probes that emit light when excited by a specific wavelength. These methods offer higher sensitivity and specificity compared to colorimetric techniques. Fluorescent dyes, such as SYBR Green for DNA and RNA or fluorescein for proteins, can detect even minute quantities of target molecules. Fluorescence-based systems are equipped with advanced imaging technologies, such as CCD cameras and UV transilluminators, to capture high-resolution images of the gels. The captured images are then analyzed using specialized software that can quantify the fluorescence intensity and provide detailed information about the molecular weight, concentration, and purity of the samples. Fluorescence-based methods also allow for multiplexing, where multiple targets can be detected simultaneously in a single gel. This is particularly useful in complex experiments where multiple genes or proteins need to be analyzed. Additionally, fluorescence-based systems can be integrated with other technologies, such as real-time PCR and next-generation sequencing, to provide comprehensive data analysis. Despite their advantages, fluorescence-based methods can be more expensive and require specialized equipment and expertise. Both colorimetric and fluorescence-based methods have their unique advantages and limitations, and the choice between them depends on the specific requirements of the experiment. In the Global Automatic Gel Documentation System Market, there is a growing trend towards the adoption of fluorescence-based systems due to their superior sensitivity, specificity, and versatility. However, colorimetric methods continue to be widely used for routine applications due to their simplicity and cost-effectiveness. The integration of advanced imaging technologies and data analysis software in automatic gel documentation systems has further enhanced the capabilities of both colorimetric and fluorescence-based methods, making them indispensable tools in modern molecular biology research.

DNA, RNA, Protein in the Global Automatic Gel Documentation System Market:

The Global Automatic Gel Documentation System Market finds extensive usage in the analysis of DNA, RNA, and proteins, which are fundamental molecules in biological research. For DNA analysis, these systems are used to visualize and quantify DNA fragments separated by gel electrophoresis. This is crucial in various applications, such as genotyping, cloning, and sequencing. The high-resolution imaging capabilities of automatic gel documentation systems allow researchers to accurately determine the size and quantity of DNA fragments, which is essential for downstream applications. Fluorescent dyes, such as SYBR Green and ethidium bromide, are commonly used to stain DNA, providing high sensitivity and specificity in detection. In RNA analysis, automatic gel documentation systems are used to assess the integrity and quantity of RNA samples. This is particularly important in gene expression studies, where the quality of RNA can significantly impact the results. The systems enable researchers to visualize RNA bands and ensure that the samples are not degraded. Fluorescent dyes, such as SYBR Gold and acridine orange, are used to stain RNA, providing clear and precise images. The ability to accurately quantify RNA is essential for applications such as quantitative PCR and RNA sequencing, where precise measurements are critical. For protein analysis, automatic gel documentation systems are used to visualize and quantify proteins separated by SDS-PAGE (sodium dodecyl sulfate-polyacrylamide gel electrophoresis). This technique is widely used in proteomics research to study protein expression, post-translational modifications, and protein-protein interactions. The systems allow researchers to capture high-resolution images of protein bands stained with dyes such as Coomassie Blue or fluorescent probes. The advanced imaging and analysis software can quantify the protein bands, providing detailed information about protein concentration and molecular weight. This is essential for applications such as Western blotting, where accurate quantification of target proteins is required. Overall, the Global Automatic Gel Documentation System Market plays a crucial role in advancing research in molecular biology by providing reliable and accurate tools for the analysis of DNA, RNA, and proteins. The integration of advanced imaging technologies and data analysis software has significantly improved the capabilities of these systems, making them indispensable in modern laboratories. The ability to automate the documentation and analysis process not only enhances efficiency but also ensures reproducibility and accuracy in experimental results. As research in genomics, proteomics, and personalized medicine continues to grow, the demand for high-quality gel documentation systems is expected to increase, further driving advancements in this market.

Global Automatic Gel Documentation System Market Outlook:

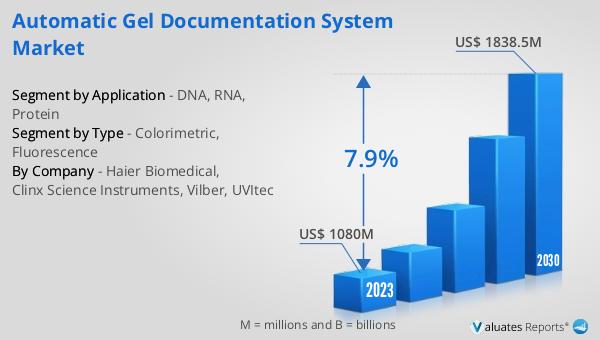

The global Automatic Gel Documentation System market was valued at US$ 1080 million in 2023 and is anticipated to reach US$ 1838.5 million by 2030, witnessing a CAGR of 7.9% during the forecast period 2024-2030. This market growth reflects the increasing demand for advanced and automated solutions in molecular biology research. The rising focus on personalized medicine, genomics, and proteomics has driven the need for precise and reliable gel documentation systems. Technological advancements, such as the integration of artificial intelligence and machine learning for enhanced data analysis, have further propelled the market. The growing adoption of fluorescence-based methods, due to their superior sensitivity and specificity, has also contributed to the market's expansion. Additionally, the increasing number of research institutions, pharmaceutical companies, and diagnostic laboratories worldwide has created a robust demand for high-throughput and automated gel documentation systems. The market's growth is also supported by the continuous development of new and innovative products by key players in the industry. Overall, the Global Automatic Gel Documentation System Market is poised for significant growth, driven by the ongoing advancements in life sciences research and the increasing need for accurate and efficient molecular diagnostics.

| Report Metric | Details |

| Report Name | Automatic Gel Documentation System Market |

| Accounted market size in 2023 | US$ 1080 million |

| Forecasted market size in 2030 | US$ 1838.5 million |

| CAGR | 7.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Haier Biomedical, Clinx Science Instruments, Vilber, UVItec |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |