What is Global Nano Silver/Nano Copper Positive Pressure Sintering Furnace Market?

The Global Nano Silver/Nano Copper Positive Pressure Sintering Furnace Market is a specialized segment within the broader materials processing industry. This market focuses on the use of advanced sintering furnaces designed to process nano-sized silver and copper particles under positive pressure conditions. These furnaces are crucial for producing high-performance materials with enhanced electrical and thermal properties, which are essential in various high-tech applications. The sintering process involves compacting and forming a solid mass of material by heat or pressure without melting it to the point of liquefaction. In the context of nano silver and nano copper, this process is particularly significant because it allows for the creation of materials with superior conductivity and strength. The market for these furnaces is driven by the increasing demand for miniaturized electronic components, efficient power devices, and advanced communication technologies. As industries continue to push the boundaries of technology, the need for materials that can perform at higher efficiencies and under more demanding conditions grows, thereby fueling the demand for these specialized sintering furnaces. The market is characterized by continuous innovation, with manufacturers striving to improve furnace efficiency, reduce processing times, and enhance the quality of the sintered products.

Fully Automatic Online Equipment (Processing Area Greater than 240mm), Semi-automatic Laboratory Equipment (Processing Area 100-240mm) in the Global Nano Silver/Nano Copper Positive Pressure Sintering Furnace Market:

Fully Automatic Online Equipment with a processing area greater than 240mm and Semi-automatic Laboratory Equipment with a processing area between 100-240mm are two critical categories within the Global Nano Silver/Nano Copper Positive Pressure Sintering Furnace Market. Fully automatic online equipment is designed for large-scale industrial applications where high throughput and precision are paramount. These systems are integrated into production lines, allowing for seamless operation and minimal human intervention. The large processing area of over 240mm enables the handling of substantial material volumes, making them ideal for mass production environments. These furnaces are equipped with advanced control systems that ensure consistent temperature and pressure conditions, which are crucial for achieving the desired material properties. The automation aspect not only enhances efficiency but also reduces the likelihood of human error, ensuring high-quality output. On the other hand, semi-automatic laboratory equipment is tailored for research and development purposes, as well as small-scale production. With a processing area ranging from 100 to 240mm, these furnaces offer flexibility and precision, making them suitable for experimental setups and prototype development. The semi-automatic nature allows for greater control over the sintering process, enabling researchers to fine-tune parameters and explore new material compositions. These furnaces are often used in academic and industrial research labs where the focus is on innovation and material discovery. Despite their smaller scale, they incorporate sophisticated technology to ensure accurate temperature and pressure control, which is essential for the sintering of nano-sized particles. Both types of equipment play a vital role in the advancement of materials science, particularly in the development of new electronic components and devices. The choice between fully automatic and semi-automatic equipment depends largely on the specific needs of the user, with considerations such as production volume, precision requirements, and budget playing a significant role. As the demand for advanced materials continues to grow, both categories of sintering furnaces are expected to see increased adoption across various industries. Manufacturers are continually working to enhance the capabilities of these furnaces, focusing on improving energy efficiency, reducing operational costs, and expanding the range of materials that can be processed. This ongoing innovation is crucial for meeting the evolving needs of industries such as electronics, automotive, and telecommunications, where the performance of materials can significantly impact the overall success of products and technologies.

Power Semiconductors, 5G Communications, Consumer Electronics, New Energy Vehicle in the Global Nano Silver/Nano Copper Positive Pressure Sintering Furnace Market:

The Global Nano Silver/Nano Copper Positive Pressure Sintering Furnace Market finds extensive applications across several high-tech industries, including power semiconductors, 5G communications, consumer electronics, and new energy vehicles. In the realm of power semiconductors, these furnaces are instrumental in producing components that require high thermal and electrical conductivity. Nano silver and nano copper materials are particularly valued for their ability to enhance the performance of semiconductor devices, which are critical for efficient power management in various electronic systems. The precise control over the sintering process provided by these furnaces ensures that the resulting materials meet the stringent quality standards required in this industry. In the field of 5G communications, the demand for materials that can support high-frequency signal transmission is paramount. Nano silver and nano copper, with their excellent conductive properties, are ideal for use in components such as antennas and connectors. The positive pressure sintering process allows for the production of materials that can withstand the demanding conditions of 5G networks, including high temperatures and rapid signal transmission rates. This capability is crucial for ensuring the reliability and efficiency of 5G infrastructure. Consumer electronics is another area where the Global Nano Silver/Nano Copper Positive Pressure Sintering Furnace Market plays a significant role. The miniaturization of electronic devices has led to an increased demand for materials that can deliver high performance in compact forms. Nano silver and nano copper are used in various components, including circuit boards and connectors, where their superior conductivity and thermal management properties are highly beneficial. The sintering furnaces enable the production of these materials with the precision and consistency needed to meet the high standards of the consumer electronics industry. In the automotive sector, particularly in the development of new energy vehicles, the use of advanced materials is critical for improving efficiency and performance. Nano silver and nano copper are used in components such as battery connectors and power electronics, where their conductive properties can enhance energy transfer and reduce losses. The positive pressure sintering process ensures that these materials are produced with the necessary quality and reliability to withstand the rigorous demands of automotive applications. As the push for more sustainable and efficient vehicles continues, the role of these advanced materials and the furnaces that produce them becomes increasingly important. Overall, the Global Nano Silver/Nano Copper Positive Pressure Sintering Furnace Market is integral to the advancement of several key industries, providing the materials needed to support innovation and technological progress.

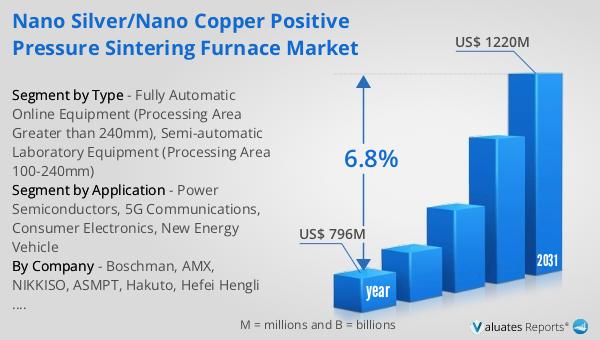

Global Nano Silver/Nano Copper Positive Pressure Sintering Furnace Market Outlook:

The market outlook for the Global Nano Silver/Nano Copper Positive Pressure Sintering Furnace Market indicates a promising growth trajectory. In 2024, the sintering furnace market was valued at approximately $796 million. Looking ahead, it is anticipated to expand significantly, reaching an estimated size of $1,220 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.8% over the forecast period. This upward trend is driven by the increasing demand for advanced materials across various industries, including electronics, automotive, and telecommunications. The need for materials with superior electrical and thermal properties is pushing manufacturers to adopt more sophisticated sintering technologies. The positive pressure sintering process, in particular, is gaining traction due to its ability to produce high-quality materials with enhanced performance characteristics. As industries continue to innovate and develop new technologies, the demand for these advanced materials is expected to rise, further fueling the growth of the sintering furnace market. This growth is also supported by ongoing research and development efforts aimed at improving the efficiency and capabilities of sintering furnaces. Manufacturers are investing in new technologies and processes to enhance the performance of their equipment, reduce operational costs, and expand the range of materials that can be processed. This focus on innovation is crucial for meeting the evolving needs of industries and ensuring the continued success of the Global Nano Silver/Nano Copper Positive Pressure Sintering Furnace Market.

| Report Metric | Details |

| Report Name | Nano Silver/Nano Copper Positive Pressure Sintering Furnace Market |

| Accounted market size in year | US$ 796 million |

| Forecasted market size in 2031 | US$ 1220 million |

| CAGR | 6.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Boschman, AMX, NIKKISO, ASMPT, Hakuto, Hefei Hengli Equipment Co., Ltd., Quick Intelligent Equipment Co., Ltd., Zhuhai Silicool Technology Co., Ltd, Shenzhen Advanced Joining Technology Co., Ltd., JHAS, TORCH, Bopaisemi, Opto-Intel Technologies Co., Ltd., Beijing Chenglian Kaida Technology Co.,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |