What is Global Nano Silver Sintering Machine Market?

The Global Nano Silver Sintering Machine Market is a rapidly evolving sector that focuses on the production and utilization of machines designed for the sintering process using nano silver particles. Sintering is a method used to create solid materials by heating powdered material below its melting point until its particles adhere to each other. Nano silver sintering machines are specifically engineered to handle silver particles at the nanoscale, which are known for their excellent thermal and electrical conductivity. These machines are crucial in industries that require high precision and reliability, such as electronics and semiconductors. The market for these machines is driven by the increasing demand for miniaturized electronic components and the need for efficient thermal management solutions. As industries continue to innovate and push the boundaries of technology, the demand for advanced sintering machines that can deliver superior performance and reliability is expected to grow. The global market is characterized by technological advancements, increased research and development activities, and a growing number of applications across various sectors. Companies in this market are focusing on developing machines that offer enhanced efficiency, reduced energy consumption, and improved operational capabilities to meet the evolving needs of their customers.

Manual Pressure Sintering Machine, Semi-Automatic Sintering Machine, Fully Automatic Sintering Machine in the Global Nano Silver Sintering Machine Market:

Manual Pressure Sintering Machines, Semi-Automatic Sintering Machines, and Fully Automatic Sintering Machines are three distinct types of equipment within the Global Nano Silver Sintering Machine Market, each offering unique features and benefits. Manual Pressure Sintering Machines are the most basic type, requiring human intervention to operate. These machines are typically used in smaller production settings or for specialized applications where precision and control are paramount. Operators manually adjust the pressure and temperature settings to achieve the desired sintering results. While they offer a high degree of control, manual machines can be labor-intensive and may not be suitable for large-scale production due to their limited throughput. On the other hand, Semi-Automatic Sintering Machines offer a balance between manual control and automation. These machines incorporate automated features such as programmable pressure and temperature controls, reducing the need for constant human intervention. They are ideal for medium-sized production runs and offer improved efficiency and consistency compared to manual machines. Semi-automatic machines allow operators to focus on quality control and other critical tasks, enhancing overall productivity. Fully Automatic Sintering Machines represent the pinnacle of technology in the sintering process. These machines are designed for high-volume production environments and feature advanced automation capabilities. They can operate continuously with minimal human intervention, thanks to sophisticated control systems that monitor and adjust the sintering parameters in real-time. Fully automatic machines offer the highest level of efficiency, consistency, and precision, making them the preferred choice for large-scale manufacturing operations. They are equipped with features such as automated loading and unloading systems, real-time data monitoring, and advanced safety mechanisms to ensure optimal performance and safety. As the demand for nano silver sintering machines continues to grow, manufacturers are focusing on developing machines that offer enhanced capabilities, such as faster processing times, improved energy efficiency, and greater flexibility to accommodate a wide range of applications. The choice between manual, semi-automatic, and fully automatic machines depends on factors such as production volume, budget, and specific application requirements. Companies must carefully evaluate their needs and consider the long-term benefits of investing in advanced sintering technology to remain competitive in the global market.

Semiconductors, Electric Vehicles, Aerospace, New Energy, Consumer Electronics in the Global Nano Silver Sintering Machine Market:

The Global Nano Silver Sintering Machine Market finds extensive usage across various industries, including semiconductors, electric vehicles, aerospace, new energy, and consumer electronics. In the semiconductor industry, nano silver sintering machines are used to create highly conductive and reliable interconnections between components. The miniaturization of electronic devices and the demand for higher performance have driven the need for advanced sintering solutions that can deliver superior thermal and electrical conductivity. Nano silver sintering machines enable the production of smaller, more efficient semiconductor devices, contributing to the overall advancement of the industry. In the electric vehicle sector, these machines play a crucial role in the production of power electronics and battery components. The high thermal conductivity of nano silver makes it an ideal material for managing heat in electric vehicle systems, ensuring optimal performance and longevity. As the demand for electric vehicles continues to rise, the need for efficient and reliable sintering solutions is expected to grow. In the aerospace industry, nano silver sintering machines are used to produce lightweight and durable components that can withstand extreme temperatures and pressures. The ability to create complex geometries and high-performance materials makes these machines invaluable in the production of aerospace components. In the new energy sector, nano silver sintering machines are used in the production of solar cells and other renewable energy technologies. The high conductivity and reliability of nano silver make it an ideal material for improving the efficiency and performance of new energy systems. Finally, in the consumer electronics industry, nano silver sintering machines are used to produce high-performance components for devices such as smartphones, tablets, and wearable technology. The demand for smaller, more powerful electronic devices has driven the need for advanced sintering solutions that can deliver superior performance and reliability. As technology continues to evolve, the Global Nano Silver Sintering Machine Market is expected to play a critical role in driving innovation and advancement across these industries.

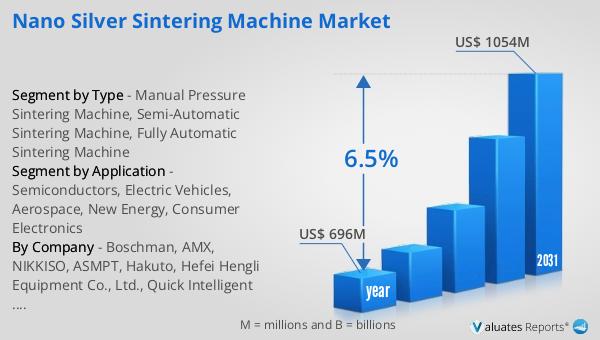

Global Nano Silver Sintering Machine Market Outlook:

The global market for Nano Silver Sintering Machines was valued at approximately $696 million in 2024, with projections indicating a growth to around $1,054 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.5% over the forecast period. The increasing demand for advanced sintering solutions across various industries, such as semiconductors, electric vehicles, aerospace, new energy, and consumer electronics, is a key driver of this market growth. As industries continue to innovate and push the boundaries of technology, the need for efficient and reliable sintering machines is expected to rise. Companies in this market are focusing on developing machines that offer enhanced capabilities, such as faster processing times, improved energy efficiency, and greater flexibility to accommodate a wide range of applications. The choice between manual, semi-automatic, and fully automatic machines depends on factors such as production volume, budget, and specific application requirements. Companies must carefully evaluate their needs and consider the long-term benefits of investing in advanced sintering technology to remain competitive in the global market. As the demand for nano silver sintering machines continues to grow, manufacturers are focusing on developing machines that offer enhanced capabilities, such as faster processing times, improved energy efficiency, and greater flexibility to accommodate a wide range of applications. The choice between manual, semi-automatic, and fully automatic machines depends on factors such as production volume, budget, and specific application requirements. Companies must carefully evaluate their needs and consider the long-term benefits of investing in advanced sintering technology to remain competitive in the global market.

| Report Metric | Details |

| Report Name | Nano Silver Sintering Machine Market |

| Accounted market size in year | US$ 696 million |

| Forecasted market size in 2031 | US$ 1054 million |

| CAGR | 6.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Boschman, AMX, NIKKISO, ASMPT, Hakuto, Hefei Hengli Equipment Co., Ltd., Quick Intelligent Equipment Co., Ltd., Zhuhai Silicool Technology Co., Ltd, Shenzhen Advanced Joining Technology Co., Ltd., JHAS, TORCH, Bopaisemi, Opto-Intel Technologies Co., Ltd., Beijing Chenglian Kaida Technology Co.,Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |