What is Global Automotive Blow Molding Machine Market?

The Global Automotive Blow Molding Machine Market is a significant segment within the manufacturing industry, focusing on the production of automotive components using blow molding technology. Blow molding is a process used to create hollow plastic parts by inflating a heated plastic tube until it fills a mold and forms the desired shape. This market is driven by the increasing demand for lightweight and durable automotive parts, which help improve fuel efficiency and reduce emissions. The automotive industry relies heavily on blow molding machines to produce a wide range of components, from fuel tanks to air ducts, due to their ability to produce complex shapes with high precision and consistency. The market is characterized by technological advancements, such as the development of more efficient and environmentally friendly machines, which are expected to drive growth. Additionally, the rise in automotive production, particularly in emerging economies, is contributing to the expansion of this market. As manufacturers strive to meet stringent environmental regulations and consumer demands for high-performance vehicles, the Global Automotive Blow Molding Machine Market is poised for continued growth and innovation.

Extrusion Blow Molding Machine, Injection Blow Molding Machine, Stretch Blow Molding Machine in the Global Automotive Blow Molding Machine Market:

In the realm of the Global Automotive Blow Molding Machine Market, three primary types of machines are pivotal: Extrusion Blow Molding Machines, Injection Blow Molding Machines, and Stretch Blow Molding Machines. Each of these machines plays a crucial role in the production of automotive components, catering to different needs and specifications. Extrusion Blow Molding Machines are widely used for manufacturing hollow parts such as fuel tanks, air ducts, and fluid reservoirs. The process involves extruding a tube of molten plastic, known as a parison, which is then clamped into a mold and inflated to take the shape of the mold cavity. This method is favored for its ability to produce large, complex shapes with uniform wall thickness, making it ideal for automotive applications where durability and precision are paramount. Injection Blow Molding Machines, on the other hand, are used for producing smaller, more intricate parts. This process involves injecting molten plastic into a preform mold to create a preform, which is then transferred to a blow mold where it is inflated to form the final product. This method is known for its high precision and ability to produce parts with excellent surface finish and dimensional accuracy, making it suitable for components such as small fluid containers and intricate under-the-hood parts. Stretch Blow Molding Machines are primarily used for producing lightweight and strong parts, such as bottles and containers, which require high clarity and impact resistance. This process involves stretching the preform both axially and radially during the blow molding process, which aligns the polymer chains and enhances the mechanical properties of the final product. In the automotive industry, stretch blow molding is particularly useful for producing components that need to withstand high pressure and temperature variations. Each of these machines offers unique advantages, and their selection depends on the specific requirements of the automotive component being produced. As the demand for lightweight, durable, and high-performance automotive parts continues to grow, the role of these blow molding machines in the Global Automotive Blow Molding Machine Market becomes increasingly vital.

Body Components, Under-the-Hood Components, Interior Components in the Global Automotive Blow Molding Machine Market:

The Global Automotive Blow Molding Machine Market finds extensive application in the production of various automotive components, including body components, under-the-hood components, and interior components. Body components, such as bumpers, fenders, and spoilers, benefit from blow molding technology due to its ability to produce large, complex shapes with consistent quality and strength. The lightweight nature of blow-molded parts contributes to improved fuel efficiency and vehicle performance, making them a preferred choice for automotive manufacturers. Under-the-hood components, including air ducts, fluid reservoirs, and engine covers, also rely heavily on blow molding machines. These components require high precision and durability to withstand the harsh conditions of the engine environment, such as high temperatures and exposure to chemicals. Blow molding technology provides the necessary strength and resistance, ensuring the longevity and reliability of these critical parts. Interior components, such as dashboard panels, door panels, and seat backs, are another area where blow molding machines play a crucial role. The ability to produce parts with intricate designs and smooth finishes makes blow molding an ideal choice for interior applications, where aesthetics and comfort are paramount. Additionally, the use of blow-molded parts in interior components helps reduce the overall weight of the vehicle, contributing to better fuel efficiency and reduced emissions. As the automotive industry continues to evolve, with a focus on sustainability and performance, the demand for blow-molded components is expected to rise. The versatility and efficiency of blow molding machines make them indispensable in the production of high-quality automotive parts, driving the growth of the Global Automotive Blow Molding Machine Market.

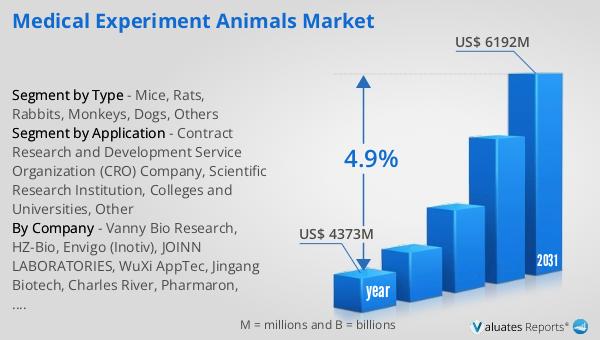

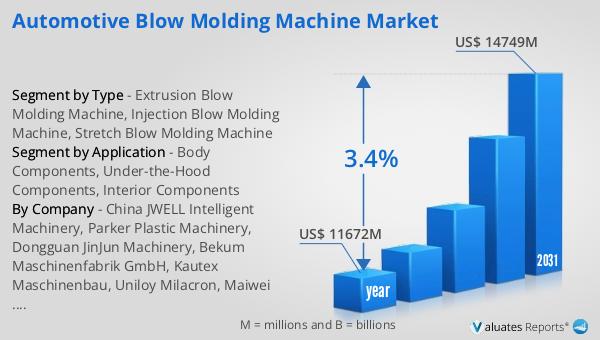

Global Automotive Blow Molding Machine Market Outlook:

In 2024, the global market for Automotive Blow Molding Machines was valued at approximately $11,672 million. This market is anticipated to experience growth, reaching an estimated value of $14,749 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.4% over the forecast period. The steady increase in market size can be attributed to several factors, including the rising demand for lightweight and durable automotive components, advancements in blow molding technology, and the expansion of the automotive industry, particularly in emerging markets. As manufacturers strive to meet stringent environmental regulations and consumer demands for high-performance vehicles, the adoption of blow molding machines is expected to rise. These machines offer the ability to produce complex shapes with high precision and consistency, making them essential in the production of various automotive components. The projected growth of the Global Automotive Blow Molding Machine Market reflects the increasing importance of blow molding technology in the automotive industry and its role in driving innovation and sustainability. As the market continues to evolve, manufacturers are likely to invest in research and development to enhance the efficiency and capabilities of blow molding machines, further fueling market growth.

| Report Metric | Details |

| Report Name | Automotive Blow Molding Machine Market |

| Accounted market size in year | US$ 11672 million |

| Forecasted market size in 2031 | US$ 14749 million |

| CAGR | 3.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | China JWELL Intelligent Machinery, Parker Plastic Machinery, Dongguan JinJun Machinery, Bekum Maschinenfabrik GmbH, Kautex Maschinenbau, Uniloy Milacron, Maiwei Machinery, Qinchuan Machine Tool & Tool Group Share, JINMING MACHINERY(GUANGDONG), Kai Mei Plastic Machinery, Shandong Tongjia Intelligent Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |